Page 19 - Mechatronics for Safety Security and Dependability in a New Era

P. 19

Ch01-I044963.fm Page 2 Monday, August 7, 2006 11:24 AM

Ch0 1-I044963 .fm

2 Page 2 Monday, August 7, 2006 11:24 AM

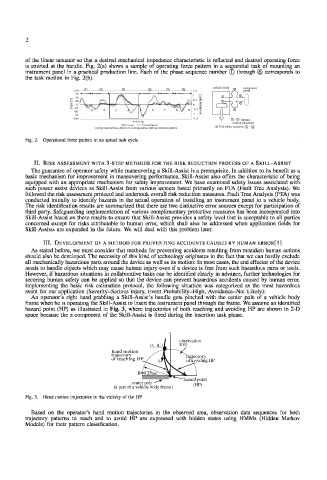

of the linear actuator so that a desired mechanical impedance characteristic is reflected and desired operating force

is exerted at the handle. Fig. 2(a) shows a sample of operating force pattern in a sequential task of mounting an

instrument panel in a practical production line. Each of the phase sequence number Q) through © corresponds to

the task motion in Fig. 2(b).

vehicle body instrument

1 2 (7) 3 4 5 6 5

100 1.5 panel

75 1 ] 2 6

50 50 s / 4

]

N / 0.5 m [

25

[ 25 (\ 3

n

e Pi / o 1

c r 0 0 i t

1 o F -25 -0.5 a r e l

4

-50 1 ^ 2 2 3 3 V 5 6 7 7 8 8 9 e c c A LJlJ 2

-75

-75 -1

-100 -1.5 1 - 6 human

time [s] motion processes

Force Acceleration n process

nce 1

-

(a) Operational force pattern in correspondence with acceleration pattern (b) Task phase sequence 1 - 6

Fig. 2. Operational force pattern in an actual task cycle

II. RISK ASSESSMENT WITH 3-STEP METHODS FOR THE RISK REDUCTION PROCESS OF A SKILL-ASSIST

The guarantee of operator safety while maneuvering a Skill-Assist is a prerequisite. In addition to its benefit as a

basic mechanism for improvement in maneuvering performance, Skill-Assist also offers the characteristic of being

equipped with an appropriate mechanism for safety improvement. We have examined safety issues associated with

such power assist devices as Skill-Assist from various aspects based primarily on FTA (Fault Tree Analysis). We

followed the risk assessment protocol and undertook overall risk reduction measures. Fault Tree Analysis (FTA) was

conducted initially to identify hazards in the actual operation of installing an instrument panel in a vehicle body.

The risk identification results arc summarized that there arc two distinctive error sources except for participation of

third party. Safeguarding implementation of various complimentary protective measures has been incorporated into

Skill-Assist based on these results to ensure that Skill-Assist provides a safety level that is acceptable to all parties

concerned except for risks attributable to human error, which shall also be addressed when application fields for

Skill-Assists are expanded in the future. We will deal with this problem later.

III. DEVELOPMENT OF A METHOD FOR PREVENTING ACCIDENTS CAUSED BY HUMAN ERRORTII

As stated before, we must consider that methods for preventing accidents resulting from mistaken human actions

should also be developed. The necessity of this kind of technology originates in the fact that we can hardly exclude

all mechanically hazardous parts around the device as well as its motion: In most cases, the end effector of the device

needs to handle objects which may cause human injury even if a device is free from such hazardous parts or tools.

However, if hazardous situations in collaborative tasks can be identified clearly in advance, further technologies for

securing human safety can be applied so that the device can prevent hazardous accidents caused by human error.

Implementing the basic risk estimation protocol, the following situation was categorized as the most hazardous

event for our application (Severity=Serious injury, Event Probability=High, Avoidance=Not Likely):

An operator's right hand grabbing a Skill-Assist's handle gets pinched with the center pole of a vehicle body

frame when he is operating the Skill-Assist to insert the instrument panel through the frame. We assume an identified

hazard point (HP) as illustrated in Fig. 3, where trajectories of both reaching and avoiding HP are shown in 2-D

space because the z component of the Skill-Assist is fixed during the insertion task phase.

x x x

observation

observation

observation

area

area

r r r , t , t , φ t φ t φ t area

t

hand motion

hand motion

hand motion

trajectory

trajectory

trajectory trajectory

jectory

trajectory

trajectory

of reachin

of reachin g g H P P of avoidin H

of reaching HP

H

of avoidin

HP

H

g

ofavoiding

g

v t v t v t of avoiding HP P P

R= 0.25 [m]

R=

0.25

R=0.25[m]

[m]

hazard point

hazard point

hazard point

hazard point

center pole

center pole -

center pole

center pole

P

P

(H

(H (HP)

(a part of a vehicle body frame)

(a part of a vehicle body frame)

(a part of a vehicle body frame) (HP) ) )

(a part of a vehicle body frame)

Fig. 3. Hand motion trajectories in the vicinity of the HP

Based on the operator's hand motion trajectories in the observed area, observation data sequences for both

trajectory patterns to reach and to avoid HP are expressed with hidden states using HMMs (Hidden Markov

Models) for their pattern classification.