Page 127 - Methods For Monitoring And Diagnosing The Efficiency Of Catalytic Converters A Patent - oriented Survey

P. 127

Toyota Motor Co. Ltd. 109

The method of EF0796985 (1997) comprises the following steps:

1) detecting the oxygen content of the exhaust gases upstream of the catalytic converter by

means of an upstream aidfitel sensor

2) detecting the oxygen content of the exhaust gases downstream of the catalytic converter by

means of a downstream aidfuel sensor

3) feedback-controlling the engine aidfitel ratio to a target aidfitel ratio in accordance with at

least the output signal of the upstream sensor

4) estimating a center of the air/fbel ratio of the catalytic converter based on a moving average

of the output of the downstream sensor

5) converting the output of the upstream oxygen sensor into a converted output in accordance

with a relationship between the difference between the output of the upstream aidfuel

sensor and the target aidfitel ratio and

a) the difference between the output of the downstream air/fhel sensor

and the target aidfitel ratio, or

b) the center estimated in step 4

6) calculating a length of the response. curve of the converted output of the upstream aidfuel

ratio sensor converted at step 5 and a length of the response curve of the downstream

sensor when the engine is controlled as in step 3

7) detecting deterioration of the catalytic converter in accordance with the upstream and

downstream lengths of step 6

8) estimating an upper and a lower limit in accordance with the center of the airhe1 ratio

estimated in step 4

9) inhibiting detection of the deterioration of the catalytic converter when the output of the

upstream sensor departs from the range between the upper limit and the lower limit

determined in step 9.

The detecting accuracy is improved by compensating for aberration of the balance between the

oxygen absorbing power and the oxygen releasing power of the converter. When there is no

balance between the power for storing oxygen and the power for releasing oxygen, there is no

accuracy in detecting the efficiency of the catalytic converter. This can be better explained by

means of fig. 54.

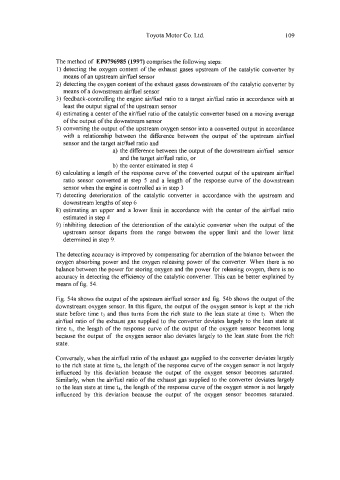

Fig. 54a shows the output of the upstream aidfitel sensor and fig. 54b shows the output of the

downstream oxygen sensor. In this figure, the output of the oxygen sensor is kept at the rich

state before time t3 and thus turns from the rich state to the lean state at time t3. When the

aidfitel ratio of the exhaust gas supplied to the converter deviates largely to the lean state at

time tl, the length of the response curve of the output of the oxygen sensor becomes long

because the output of the oxygen sensor also deviates largely to the lean state from the rich

state.

Conversely, when the aidfhel ratio of the exhaust gas supplied to the converter deviates largely

to the rich state at time t2, the length of the response curve of the oxygen sensor is not largely

influenced by this deviation because the output of the oxygen sensor becomes saturated.

Similarly, when the aidfuel ratio of the exhaust gas supplied to the converter deviates largely

to the lean state at time t+ the length of the response curve of the oxygen sensor is not largely

influenced by this deviation because the output of the oxygen sensor becomes saturated.