Page 308 - Methods For Monitoring And Diagnosing The Efficiency Of Catalytic Converters A Patent - oriented Survey

P. 308

290 Methods for Monitoring and Diagnosing the Efficiency of Catalytic Converters

temperature in field conditions of the vehicle. The period of time for the test is determined

from the relationship between the catalyst bed temperature and the deterioration of the catalyst

so as to obtain the same extent of deterioration as that under field conditions. So the time of

the test can be much shorter than that under field conditions of the vehicle.

The method of JP8270438 (1996) comprises the following steps:

1) measuring the actual temperature of a catalytic converter by means of a temperature sensor

2) estimating the temperature of the converter, if the converter has a predetermined

deterioration grade, based on the actual operating condition of the engine and the external

environment of the converter

3) calculating the difference between the actual and the estimated temperature values of the

converter

4) assessing the efficiency of the catalytic converter from the calculate temperature difference

of step 3.

The method of JP8284648 (1996) is based on the fact that the activation time of a deteriorated

catalytic converter is longer than the activation time of an efficient catalytic converter. An

oxygen sensor is installed downstream of the catalytic converter. The time required for the

sensor to be warmed up to its activation temperature is measured starting from cool engine

conditions. The catalytic converter is judged as deteriorated when the measured value of

activation time of the sensor is larger than a predefined threshold.

The method of patent application EP0756071 (1997)comprises the steps of

1) measuring the temperature 7; in the center portion of the downstream side of the catalytic

converter

2) assuming a temperature 7;' in the center portion of the downstream side of the catalytic

converter on the basis of the operation condition of the engine

3) calculating a ratio of a varying value of the measured temperature T, (step 1) to a varying

value of the assumed temperature (step 2)

4) determining that the catalytic converter is deteriorated when said ratio is smaller than a

predetermined value.

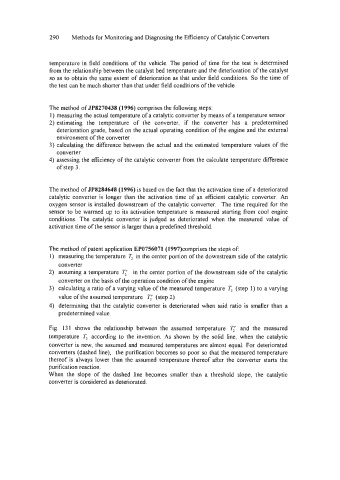

Fig. 131 shows the relationship between the assumed temperature and the measured

temperature according to the invention. As shown by the solid line, when the catalytic

converter is new, the assumed and measured temperatures are almost equal. For deteriorated

converters (dashed line), the purification becomes so poor so that the measured temperature

thereof is always lower than the assumed temperature thereof after the converter starts the

purification reaction.

When the slope of the dashed line becomes smaller than a threshold slope, the catalytic

converter is considered as deteriorated.