Page 127 - Modular design for machine tools

P. 127

88 Modular Design Guide and Machine Tools Description

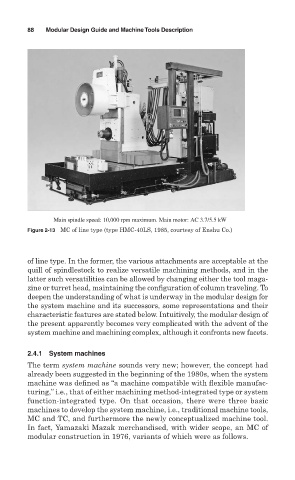

Main spindle speed: 10,000 rpm maximum. Main motor: AC 3.7/5.5 kW

Figure 2-13 MC of line type (type HMC-40LS, 1985, courtesy of Enshu Co.)

of line type. In the former, the various attachments are acceptable at the

quill of spindlestock to realize versatile machining methods, and in the

latter such versatilities can be allowed by changing either the tool maga-

zine or turret head, maintaining the configuration of column traveling. To

deepen the understanding of what is underway in the modular design for

the system machine and its successors, some representations and their

characteristic features are stated below. Intuitively, the modular design of

the present apparently becomes very complicated with the advent of the

system machine and machining complex, although it confronts new facets.

2.4.1 System machines

The term system machine sounds very new; however, the concept had

already been suggested in the beginning of the 1980s, when the system

machine was defined as “a machine compatible with flexible manufac-

turing,” i.e., that of either machining method-integrated type or system

function-integrated type. On that occasion, there were three basic

machines to develop the system machine, i.e., traditional machine tools,

MC and TC, and furthermore the newly conceptualized machine tool.

In fact, Yamazaki Mazak merchandised, with wider scope, an MC of

modular construction in 1976, variants of which were as follows.