Page 133 - Modular design for machine tools

P. 133

Engineering Guides and Future Perspectives of Modular Design 93

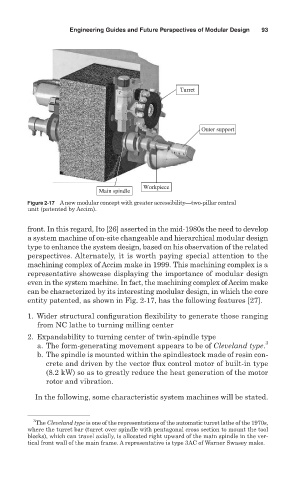

Turret

Outer support

Workpiece

Main spindle

Figure 2-17 A new modular concept with greater accessibility— two-pillar central

unit (patented by Accim).

front. In this regard, Ito [26] asserted in the mid-1980s the need to develop

a system machine of on-site changeable and hierarchical modular design

type to enhance the system design, based on his observation of the related

perspectives. Alternately, it is worth paying special attention to the

machining complex of Accim make in 1999. This machining complex is a

representative showcase displaying the importance of modular design

even in the system machine. In fact, the machining complex of Accim make

can be characterized by its interesting modular design, in which the core

entity patented, as shown in Fig. 2-17, has the following features [27].

1. Wider structural configuration flexibility to generate those ranging

from NC lathe to turning milling center

2. Expandability to turning center of twin-spindle type

a. The form-generating movement appears to be of Cleveland type. 3

b. The spindle is mounted within the spindlestock made of resin con-

crete and driven by the vector flux control motor of built-in type

(8.2 kW) so as to greatly reduce the heat generation of the motor

rotor and vibration.

In the following, some characteristic system machines will be stated.

3

The Cleveland type is one of the representations of the automatic turret lathe of the 1970s,

where the turret bar (turret over spindle with pentagonal cross section to mount the tool

blocks), which can travel axially, is allocated right upward of the main spindle in the ver-

tical front wall of the main frame. A representative is type 3AC of Warner Swasey make.