Page 83 - Modular design for machine tools

P. 83

50 Modular Design Guide and Machine Tools Description

both the NC software and the number of control axes, although the soft-

ware has certain limitations. When the required flexibility of the

machine tool is far beyond that given by the software available, the

machine must be restructured to reinforce the machine flexibility using

the modular design.

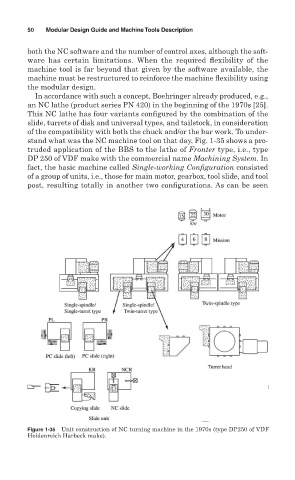

In accordance with such a concept, Boehringer already produced, e.g.,

an NC lathe (product series PN 420) in the beginning of the 1970s [25].

This NC lathe has four variants configured by the combination of the

slide, turrets of disk and universal types, and tailstock, in consideration

of the compatibility with both the chuck and/or the bar work. To under-

stand what was the NC machine tool on that day, Fig. 1-35 shows a pro-

truded application of the BBS to the lathe of Fronter type, i.e., type

DP 250 of VDF make with the commercial name Machining System. In

fact, the basic machine called Single-working Configuration consisted

of a group of units, i.e., those for main motor, gearbox, tool slide, and tool

post, resulting totally in another two configurations. As can be seen

Figure 1-35 Unit construction of NC turning machine in the 1970s (type DP250 of VDF

Heidenreich Harbeck make).