Page 93 - Modular design for machine tools

P. 93

58 Modular Design Guide and Machine Tools Description

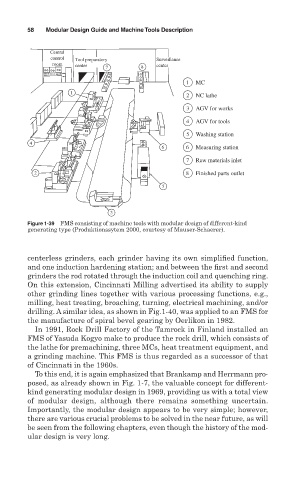

Central

control Tool preparatory Surveillance

room center center

7 8

1 MC

1

2 NC lathe

3 AGV for works

4 AGV for tools

5 Washing station

4

6 6 Measuring station

7 Raw materials inlet

2 8 Finished parts outlet

5

3

Figure 1-39 FMS consisting of machine tools with modular design of different-kind

generating type (Produktionssytem 2000, courtesy of Mauser-Schaerer).

centerless grinders, each grinder having its own simplified function,

and one induction hardening station; and between the first and second

grinders the rod rotated through the induction coil and quenching ring.

On this extension, Cincinnati Milling advertised its ability to supply

other grinding lines together with various processing functions, e.g.,

milling, heat treating, broaching, turning, electrical machining, and/or

drilling. A similar idea, as shown in Fig.1-40, was applied to an FMS for

the manufacture of spiral bevel gearing by Oerlikon in 1982.

In 1991, Rock Drill Factory of the Tamrock in Finland installed an

FMS of Yasuda Kogyo make to produce the rock drill, which consists of

the lathe for premachining, three MCs, heat treatment equipment, and

a grinding machine. This FMS is thus regarded as a successor of that

of Cincinnati in the 1960s.

To this end, it is again emphasized that Brankamp and Herrmann pro-

posed, as already shown in Fig. 1-7, the valuable concept for different-

kind generating modular design in 1969, providing us with a total view

of modular design, although there remains something uncertain.

Importantly, the modular design appears to be very simple; however,

there are various crucial problems to be solved in the near future, as will

be seen from the following chapters, even though the history of the mod-

ular design is very long.