Page 199 - New Trends in Eco efficient and Recycled Concrete

P. 199

Main

Application

Processing

Density

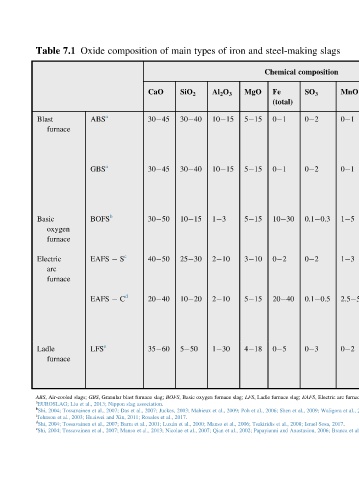

MnO properties (g/cm 3 ) Free P 2 O 5 TiO 2 CaO Crystalline, and Concrete cooling Slow 2.5 0 0.1 0 1 density, road (air strength aggregate cooled), crushing, sieving Vitreous, Cement, cooling Rapid 0 0.1 0 1 hydraulic concrete (water addition cooled), gridding (,100 μm) Crystalline,

slags composition SO 3 0 2 0 2 0.1 0.3 0 2 0.1 0.5 0 3 e Shi, 2004; Tossavainen et al., 2007; Manso et al., 2013; Nicolae et al., 2007; Qian et al., 2002; Papayianni and Anastasiou, 2006; Branca et al., 2009; Rodriguez et al., 2009; Setie ´n et al., 2009; Papayianni and Anastasiou, 2010; Montenegro et al., 2013.

steel-making Chemical Fe (total) 0 1 0 1 10 30 0 2 20 40 0 5

and MgO 5 15 5 15 5 15 3 10 5 15 4 18

iron

of Al 2 O 3 10 15 10 15 1 3 2 10 2 10 1 30 b Shi, 2004; Tossavainen et al., 2007; Das et al., 2007; Juckes, 2003; Mahieux et al., 2009; Poh et al., 2006; Shen et al., 2009; Waligora et al., 2010; Xuequan et al., 1999.

types ABS, Air-cooled slags; GBS, Granular blast furnace slag; BOFS, Basic oxygen furnace slag; LFS, Ladle furnace slag; EAFS, Electric arc furnace slag.

main SiO 2 30 40 30 40 10 15 25 30 10 20 5 50 d Shi, 2004; Tossavainen et al., 2007; Barra et al., 2001; Luxa ´n et al., 2000; Manso et al., 2006; Tsakiridis et al., 2008; Israel Sosa, 2017.

of CaO 30 45 30 45 30 50 40 50 20 40 35 60

composition S c C d

Oxide ABS a GBS a BOFS b EAFS EAFS LFS e a EUROSLAG; Liu et al., 2013; Nippon slag association. c Johnson et al., 2003; Huaiwei and Xin, 2011; Rosales et al., 2017.

7.1 furnace oxygen furnace furnace furnace

Table Blast Basic Electric arc Ladle