Page 407 - New Trends in Eco efficient and Recycled Concrete

P. 407

362 New Trends in Eco-efficient and Recycled Concrete

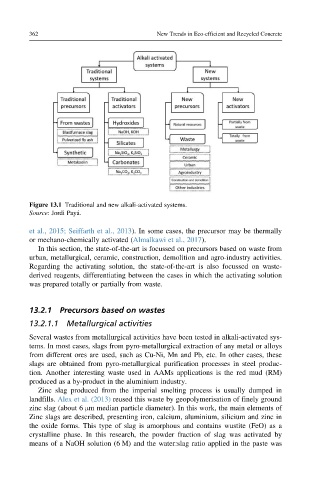

Figure 13.1 Traditional and new alkali-activated systems.

Source: Jordi Paya ´.

et al., 2015; Seiffarth et al., 2013). In some cases, the precursor may be thermally

or mechano-chemically activated (Almalkawi et al., 2017).

In this section, the state-of-the-art is focussed on precursors based on waste from

urban, metallurgical, ceramic, construction, demolition and agro-industry activities.

Regarding the activating solution, the state-of-the-art is also focussed on waste-

derived reagents, differentiating between the cases in which the activating solution

was prepared totally or partially from waste.

13.2.1 Precursors based on wastes

13.2.1.1 Metallurgical activities

Several wastes from metallurgical activities have been tested in alkali-activated sys-

tems. In most cases, slags from pyro-metallurgical extraction of any metal or alloys

from different ores are used, such as Cu-Ni, Mn and Pb, etc. In other cases, these

slags are obtained from pyro-metallurgical purification processes in steel produc-

tion. Another interesting waste used in AAMs applications is the red mud (RM)

produced as a by-product in the aluminium industry.

Zinc slag produced from the imperial smelting process is usually dumped in

landfills. Alex et al. (2013) reused this waste by geopolymerisation of finely ground

zinc slag (about 6 μm median particle diameter). In this work, the main elements of

Zinc slags are described, presenting iron, calcium, aluminium, silicium and zinc in

the oxide forms. This type of slag is amorphous and contains wustite (FeO) as a

crystalline phase. In this research, the powder fraction of slag was activated by

means of a NaOH solution (6 M) and the water:slag ratio applied in the paste was