Page 445 - New Trends in Eco efficient and Recycled Concrete

P. 445

Application of alkali-activated industrial waste 397

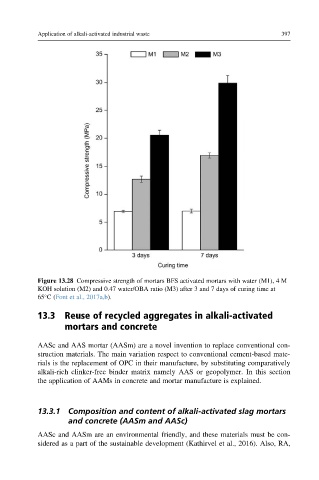

Figure 13.28 Compressive strength of mortars BFS activated mortars with water (M1), 4 M

KOH solution (M2) and 0.47 water/OBA ratio (M3) after 3 and 7 days of curing time at

65 C(Font et al., 2017a,b).

13.3 Reuse of recycled aggregates in alkali-activated

mortars and concrete

AASc and AAS mortar (AASm) are a novel invention to replace conventional con-

struction materials. The main variation respect to conventional cement-based mate-

rials is the replacement of OPC in their manufacture, by substituting comparatively

alkali-rich clinker-free binder matrix namely AAS or geopolymer. In this section

the application of AAMs in concrete and mortar manufacture is explained.

13.3.1 Composition and content of alkali-activated slag mortars

and concrete (AASm and AASc)

AASc and AASm are an environmental friendly, and these materials must be con-

sidered as a part of the sustainable development (Kathirvel et al., 2016). Also, RA,