Page 33 - Oil and Gas Production Handbook An Introduction to Oil and Gas Production

P. 33

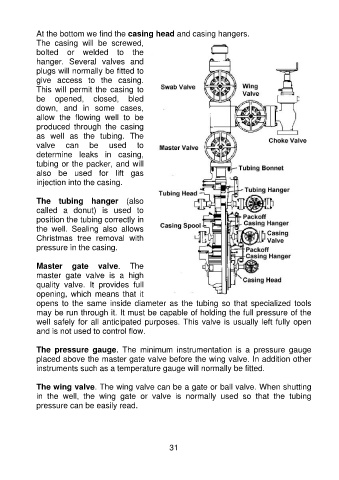

At the bottom we find the casing head and casing hangers.

The casing will be screwed,

bolted or welded to the

hanger. Several valves and

plugs will normally be fitted to

give access to the casing.

This will permit the casing to

be opened, closed, bled

down, and in some cases,

allow the flowing well to be

produced through the casing

as well as the tubing. The

valve can be used to

determine leaks in casing,

tubing or the packer, and will

also be used for lift gas

injection into the casing.

The tubing hanger (also

called a donut) is used to

position the tubing correctly in

the well. Sealing also allows

Christmas tree removal with

pressure in the casing.

Master gate valve. The

master gate valve is a high

quality valve. It provides full

opening, which means that it

opens to the same inside diameter as the tubing so that specialized tools

may be run through it. It must be capable of holding the full pressure of the

well safely for all anticipated purposes. This valve is usually left fully open

and is not used to control flow.

The pressure gauge. The minimum instrumentation is a pressure gauge

placed above the master gate valve before the wing valve. In addition other

instruments such as a temperature gauge will normally be fitted.

The wing valve. The wing valve can be a gate or ball valve. When shutting

in the well, the wing gate or valve is normally used so that the tubing

pressure can be easily read.

31