Page 80 - Open-Hole Log Analysis and Formation Evaluation

P. 80

Y

ai

Ala

VAIIA

yj

ANIA

Core

Inner

bit

Bearing

Core ‘ore bit (

barrel

Outer barrel

catcher

assembly

(see detail )

/

Bit face

is

to

or crown

fig.

may

This

from

Cores

For

World

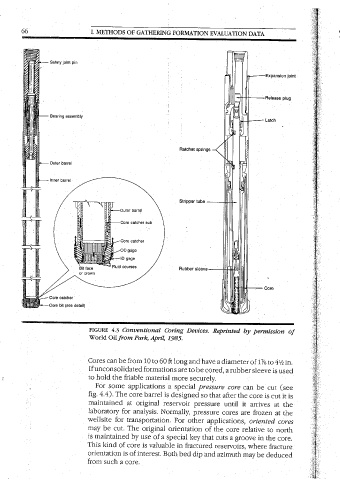

FIGURE

“==

hold

be

wellsite

4.4).

can

kind

such

laboratory

4.3

orientation

the

maintained

for

a

cut.

of

some

be

is

The

maintained

for

at

Oil from

Fluid courses

by

The

core.

core

core

from

Outer barrel

friable

Core catcher

is

Park,

10

use

Core catcher sub

analysis.

to

original

Conventional

of interest.

barrel

applications

ofa

April,

original

60

is

i Y vy, y ye i. Safety joint pin 7 ee ja=y DATA FORMATION EVALUATION I METHODS OF GATHERING 66

material

transportation.

a

ft

valuable

Both

1985.

in

Coring

For

Ifunconsolidated formations are

special

more

Normally,

reservoir

bed

Rubber

Ratchet

special

designed

key

orientation

dip

to be

other

Stripper tube

sleeve

so

Devices.

springs

of

fractured

that

long and have

and

securely.

pressure

pressure

a

that

the

cored,

pressure

cuts

a

after

cores

until

core

Reprinted

core

azimuth

applications,

reservoirs,

it

the

by

|

are

can

groove

core

may be

__——-

be

in

relative

diameter of 17%

where

is

arrives

a rubber sleeve

frozen

to

Core

the

oriented

Latch

is

cut

at

at

cut

Release

to 4%

permission

Expansion

it

plug

deduced

in.

the

north

core.

fracture

used

the

is

(see

cores

of

Regulator—___

Inner barrel—___

iN

|

fs

N

‘ Spring joint——__hY] joint en Latch— oT

i

4.

- Bit: Gore catcher Ball valve Upper seal ring reservolr G as CORING

=

FIGURE. 4.4

Jrom Park,

April,

Pressure

: 1985, Core Barrel. Reprinted by Core bit (see Core catcher Inner barrel Outer barrel assembly Bearing Extension rod Non-magnetic Survey tool

detail)

5 on of World Oil permi ring Retaining ane . Scribes Core catcher barrel Outer drill collar