Page 156 - Packed bed columns for absorption, desorption, rectification and direct heat transfer

P. 156

151

reduction of the length of the film lead to reduction of the diffusion layer and in

this way to increasing of the mass transfer coefficient.

Consequently from the point of view of the mass transfer theory, the

intensification of the packed bed column can be achieved in the following two

ways:

1. Creating packings which allow operation at high gas and liquid

superficial velocities at small hydraulic diameter of the packing;

2. Creating packings which promote frequent breaks of the liquid film,

and coalescence and break of the drops and jets in the packing free volume.

From economical point of view the packings must have also low

pressure drop, low price, corrosion stability, and so on.

Usually the packings are compared on the base of their pressure drop

per one mass transfer unit as a function of F G:

= f(F G)- (2)

NTU G

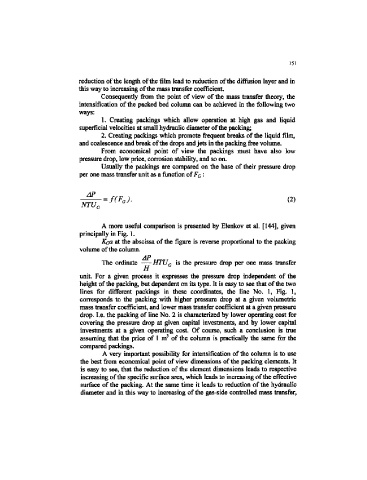

A more useful comparison is presented by Elenkov et al. [144], given

principally in Fig. 1.

Kca at the abscissa of the figure is reverse proportional to the packing

volume of the column.

The ordinate HTU G is the pressure drop per one mass transfer

unit. For a given process it expresses the pressure drop independent of the

height of the packing, but dependent on its type. It is easy to see that of the two

lines for different packings in these coordinates, the line No. 1, Fig. 1,

corresponds to the packing with higher pressure drop at a given volumetric

mass transfer coefficient, and lower mass transfer coefficient at a given pressure

drop. Le. the packing of line No. 2 is characterized by lower operating cost for

covering the pressure drop at given capital investments, and by lower capital

investments at a given operating cost. Of course, such a conclusion is true

3

assuming that the price of 1 m of the column is practically the same for the

compared packings.

A very important possibility for intensification of the column is to use

the best from economical point of view dimensions of the packing elements. It

is easy to see, that the reduction of the element dimensions leads to respective

increasing of the specific surface area, which leads to increasing of the effective

surface of the packing. At the same time it leads to reduction of the hydraulic

diameter and in this way to increasing of the gas-side controlled mass transfer,