Page 188 - Petroleum and Gas Field Processing

P. 188

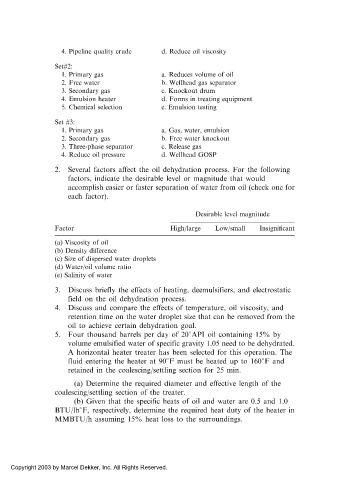

4. Pipeline quality crude d. Reduce oil viscosity

Set#2:

1. Primary gas a. Reduces volume of oil

2. Free water b. Wellhead gas separator

3. Secondary gas c. Knockout drum

4. Emulsion heater d. Forms in treating equipment

5. Chemical selection e. Emulsion testing

Set #3:

1. Primary gas a. Gas, water, emulsion

2. Secondary gas b. Free water knockout

3. Three-phase separator c. Release gas

4. Reduce oil pressure d. Wellhead GOSP

2. Several factors affect the oil dehydration process. For the following

factors, indicate the desirable level or magnitude that would

accomplish easier or faster separation of water from oil (check one for

each factor).

Desirable level magnitude

Factor High/large Low/small Insignificant

(a) Viscosity of oil

(b) Density difference

(c) Size of dispersed water droplets

(d) Water/oil volume ratio

(e) Salinity of water

3. Discuss briefly the effects of heating, deemulsifiers, and electrostatic

field on the oil dehydration process.

4. Discuss and compare the effects of temperature, oil viscosity, and

retention time on the water droplet size that can be removed from the

oil to achieve certain dehydration goal.

5. Four thousand barrels per day of 20 API oil containing 15% by

volume emulsified water of specific gravity 1.05 need to be dehydrated.

A horizontal heater treater has been selected for this operation. The

fluid entering the heater at 90 F must be heated up to 160 Fand

retained in the coalescing/settling section for 25 min.

(a) Determine the required diameter and effective length of the

coalescing/settling section of the treater.

(b) Given that the specific heats of oil and water are 0.5 and 1.0

BTU/lb F, respectively, determine the required heat duty of the heater in

MMBTU/h assuming 15% heat loss to the surroundings.

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.