Page 206 - Petroleum and Gas Field Processing

P. 206

Gas: dissolved gases in varying amounts depending on the

gas–oil ratio (GOR)

Hydrogen Sulfide: up to 1000 ppm by weight

(b) After treatment (dual-purpose operation): Sour wet crude

must be treated to make it safe and environmentally acceptable

for storage, processing, and export. Therefore, removing water

and salt, as in Chapters 5 and 6, respectively, is mandatory

to avoid corrosion; separation of gases and H 2 S will make

crude oil safe and environmentally acceptable to handle.

Water content (B.S.&W.): 0.3% by volume, maximum

Salt content: 10–20 lbs salt (NaCl) per 1000 barrels oil (PTB)

Vapor pressure: 5–20 psia RVP (Reid vapor pressure)

H 2 S: 10–100 ppmw

Crude oil is considered ‘‘sweet’’ if the dangerous acidic gases are

removed from it. On the other hand, it is classified as ‘‘sour’’ if it contains

3

as much as 0.05 ft of dissolved H 2 S in 100 gal of oil. Hydrogen sulfide gas

is a poison hazard because 0.1% in air is toxically fatal in 30 min.

Additional processing is mandatory—via this dual operation—in order to

release any residual associated gases along with H 2 S present in the crude.

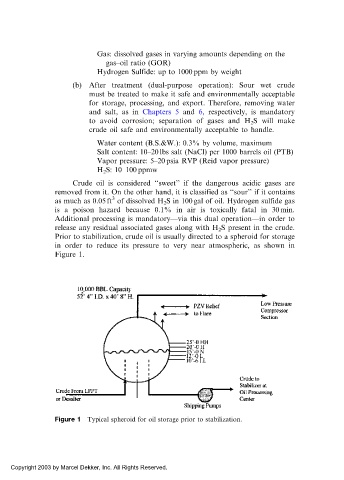

Prior to stabilization, crude oil is usually directed to a spheroid for storage

in order to reduce its pressure to very near atmospheric, as shown in

Figure 1.

Figure 1 Typical spheroid for oil storage prior to stabilization.

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.