Page 381 - Pipeline Pigging Technology

P. 381

Pipeline Pigging Technology

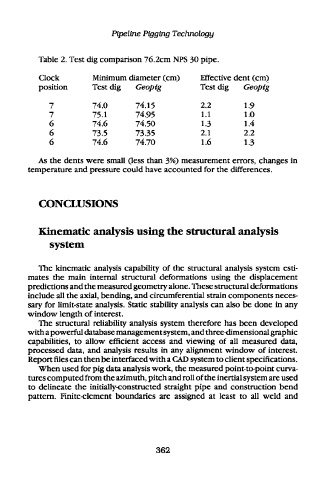

Table 2. Test dig comparison 76.2cm NFS 30 pipe.

Clock Minimum diameter (cm) Effective dent (cm)

position Test dig Geoptg Test dig Geopig

7 74.0 74.15 2.2 1.9

7 75.1 74.95 1.1 1.0

6 74.6 74.50 1.3 1.4

6 73.5 73.35 2.1 2.2

6 74.6 74.70 1.6 1.3

As the dents were small (less than 3%) measurement errors, changes in

temperature and pressure could have accounted for the differences.

CONCLUSIONS

Kinematic analysis using the structural analysis

system

The kinematic analysis capability of the structural analysis system esti-

mates the main internal structural deformations using the displacement

predictions and the measured geometry alone. These structural deformations

include all the axial, bending, and circumferential strain components neces-

sary for limit-state analysis. Static stability analysis can also be done in any

window length of interest.

The structural reliability analysis system therefore has been developed

with a powerful database management system, and three-dimensional graphic

capabilities, to allow efficient access and viewing of all measured data,

processed data, and analysis results in any alignment window of interest.

Report files can then be interfaced with a CAD system to client specifications.

When used for pig data analysis work, the measured point-to-point curva-

tures computed from the azimuth, pitch and roll of the inertial system are used

to delineate the initially-constructed straight pipe and construction bend

pattern. Finite-element boundaries are assigned at least to all weld and

362