Page 56 - Pipelines and Risers

P. 56

Wall-thickness and Material Grade Selection 29

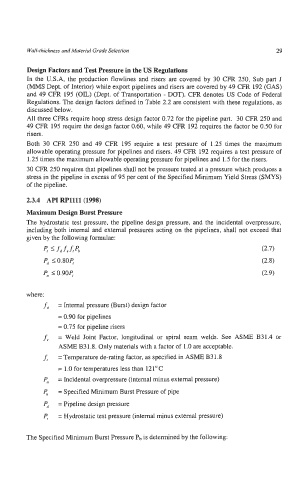

Design Factors and Test Pressure in the US Regulations

In the U.S.A, the production flowlines and risers are covered by 30 CFR 250, Sub part J

(MMS Dept. of Interior) while export pipelines and risers are covered by 49 CFR 192 (GAS)

and 49 CFR 195 (OIL) (Dept. of Transportation - DOT). CFR denotes US Code of Federal

Regulations. The design factors defined in Table 2.2 are consistent with these regulations, as

discussed below.

AI1 three CFRs require hoop stress design factor 0.72 for the pipeline part. 30 CFR 250 and

49 CFR 195 require the design factor 0.60, while 49 CFR 192 requires the factor be 0.50 for

risers.

Both 30 CFR 250 and 49 CFR 195 require a test pressure of 1.25 times the maximum

allowable operating pressure for pipelines and risers. 49 CFR 192 requires a test pressure of

1.25 times the maximum allowable operating pressure for pipelines and 1.5 for the risers.

30 CFR 250 requires that pipelines shall not be pressure tested at a pressure which produces a

stress in the pipeline in excess of 95 per cent of the Specified Minimum Yield Stress (SMYS)

of the pipeline.

2.3.4 API RPllll (1998)

Maximum Design Burst Pressure

The hydrostatic test pressure, the pipeline design pressure, and the incidental overpressure,

including both internal and external pressures acting on the pipelines, shall not exceed that

given by the following formulae:

P, 5 fdf,f,p, (2.7)

Pd 50.80P, (2.8)

Pa <0.90P, (2.9)

where:

f,, = Internal pressure (Burst) design factor

= 0.90 for pipelines

= 0.75 for pipeline risers

f, = Weld Joint Factor, longitudinal or spiral seam welds. See ASME B31.4 or

ASME B31.8. Only materials with a factor of 1.0 are acceptable.

f, = Temperature de-rating factor, as specified in ASME B31.8

= 1.0 for temperatures less than 121°C

Pa = Incidental overpressure (internal minus external pressure)

= Specified Minimum Burst Pressure of pipe

P,, = Pipeline design pressure

P, = Hydrostatic test pressure (internal minus external pressure)

The Specified Minimum Burst Pressure Pb is determined by the following: