Page 94 - Pipelines and Risers

P. 94

Limit-state based Strength Design 67

4.4 Local BucklinglCollapse

This section is based on Hauch and Bai (1999).

Local Buckling

For pipelines subjected to combined pressure, longitudinal force and bending, local buckling

may occur. The failure mode may be yielding of the cross section or buckling on the

compressive side of the pipe. The criteria given in this guideline may be used to calculate the

maximum allowable bending moment for a given scenario. It shall be noted that the maximum

allowable bending moment given in this guideline does not take fracture into account and that

fracture criteria therefore may reduce the bending capacity of the pipe. This particularly

applies for high-tensionhigh-pressure load conditions.

Load Versus Displacement Controlled Situations

The local buckling check can be separated into a check for load controlled situations (bending

moment) and one for displacement controlled situations (strain level). Due to the relation

between applied bending moment and maximum strain in a pipe, a higher allowable strength

for a given target safety level can be achieved by using a strain-based criterion than the

bending moment criterion. Consequently the bending moment criterion can, conservatively be

used for both load and displacement controlled situations. In this guideline only the bending

moment criterion is given.

Local Buckling and Accumulated Out-of-Roundness

Increased out-of-roundness due to installation and cyclic operating loads may aggravate local

buckling and is to be considered. It is recommended that out-of-roundness due to through life

loads be simulated using finite element analysis.

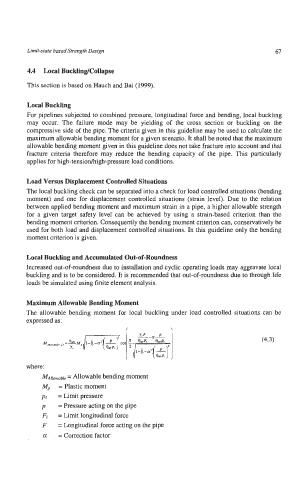

Maximum Allowable Bending Moment

The allowable bending moment for local buckling under load controlled situations can be

expressed as:

I \

(4.3)

where:

MAllowable = Allowable bending moment

Mp = Plastic moment

pL = Limit pressure

p = Pressure acting on the pipe

Fl = Limit longitudinal force

F = bngitudinal force acting on the pipe

a! = Correction factor