Page 63 - Piston Engine-Based Power Plants

P. 63

Diesel Engines 55

One of the advantages of large two-stroke engines is their simplic-

ity. The engines have no valves and so requires fewer parts. Another

major advantage is the ability of these engines to burn heavy fuel oil

with high efficiency. This heavy or residual fuel oil is the fraction left

after all the more valuable parts of crude oil have been removed by

fractional distillation. It is a cheap fuel but extremely dirty so plants

that burn it need extensive emission control facilities. This can be cost-

effective in a large plant whereas it might not be in a small diesel

engine generating unit.

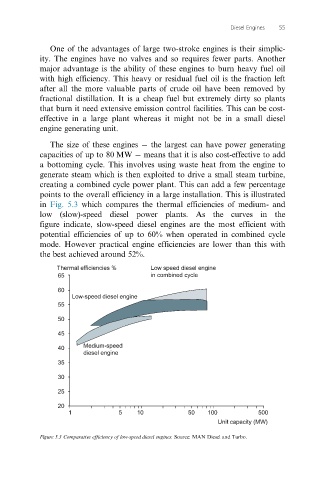

The size of these engines the largest can have power generating

capacities of up to 80 MW means that it is also cost-effective to add

a bottoming cycle. This involves using waste heat from the engine to

generate steam which is then exploited to drive a small steam turbine,

creating a combined cycle power plant. This can add a few percentage

points to the overall efficiency in a large installation. This is illustrated

in Fig. 5.3 which compares the thermal efficiencies of medium- and

low (slow)-speed diesel power plants. As the curves in the

figure indicate, slow-speed diesel engines are the most efficient with

potential efficiencies of up to 60% when operated in combined cycle

mode. However practical engine efficiencies are lower than this with

the best achieved around 52%.

Thermal efficiencies % Low speed diesel engine

65 in combined cycle

60

Low-speed diesel engine

55

50

45

Medium-speed

40

diesel engine

35

30

25

20

1 5 10 50 100 500

Unit capacity (MW)

Figure 5.3 Comparative efficiency of low-speed diesel engines. Source: MAN Diesel and Turbo.