Page 83 - Piston Engine-Based Power Plants

P. 83

74 Piston Engine-Based Power Plants

Customer heat

exchanger Exhaust

Engine

Heat

recovery Gear

Excess heat box

exchanger

T

Oil cooler

Jacket water

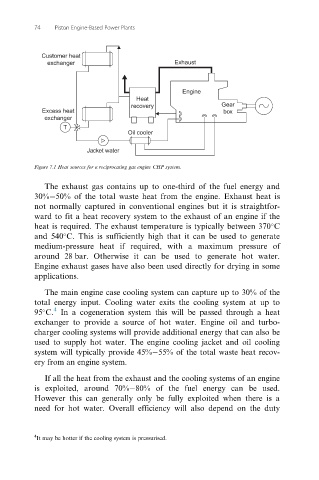

Figure 7.1 Heat sources for a reciprocating gas engine CHP system.

The exhaust gas contains up to one-third of the fuel energy and

30% 50% of the total waste heat from the engine. Exhaust heat is

not normally captured in conventional engines but it is straightfor-

ward to fit a heat recovery system to the exhaust of an engine if the

heat is required. The exhaust temperature is typically between 370 C

and 540 C. This is sufficiently high that it can be used to generate

medium-pressure heat if required, with a maximum pressure of

around 28 bar. Otherwise it can be used to generate hot water.

Engine exhaust gases have also been used directly for drying in some

applications.

The main engine case cooling system can capture up to 30% of the

total energy input. Cooling water exits the cooling system at up to

4

95 C. In a cogeneration system this will be passed through a heat

exchanger to provide a source of hot water. Engine oil and turbo-

charger cooling systems will provide additional energy that can also be

used to supply hot water. The engine cooling jacket and oil cooling

system will typically provide 45% 55% of the total waste heat recov-

ery from an engine system.

If all the heat from the exhaust and the cooling systems of an engine

is exploited, around 70% 80% of the fuel energy can be used.

However this can generally only be fully exploited when there is a

need for hot water. Overall efficiency will also depend on the duty

4 It may be hotter if the cooling system is pressurised.