Page 156 - Plant design and economics for chemical engineers

P. 156

130 PLANT DESIGN AND ECONOMICS FOR CHEMICAL ENGINEERS

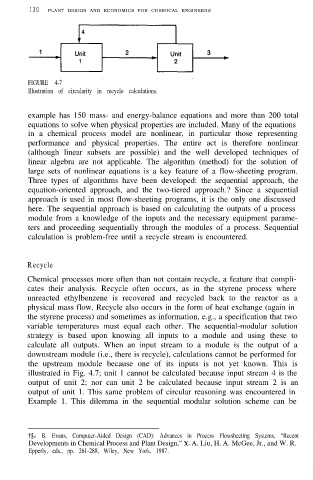

FIGURE 4-7

Illustration of circularity in recycle calculations.

example has 150 mass- and energy-balance equations and more than 200 total

equations to solve when physical properties are included. Many of the equations

in a chemical process model are nonlinear, in particular those representing

performance and physical properties. The entire act is therefore nonlinear

(although linear subsets are possible) and the well developed techniques of

linear algebra are not applicable. The algorithm (method) for the solution of

large sets of nonlinear equations is a key feature of a flow-sheeting program.

Three types of algorithms have been developed: the sequential approach, the

equation-oriented approach, and the two-tiered approach.? Since a sequential

approach is used in most flow-sheeting programs, it is the only one discussed

here. The sequential approach is based on calculating the outputs of a process

module from a knowledge of the inputs and the necessary equipment parame-

ters and proceeding sequentially through the modules of a process. Sequential

calculation is problem-free until a recycle stream is encountered.

Recycle

Chemical processes more often than not contain recycle, a feature that compli-

cates their analysis. Recycle often occurs, as in the styrene process where

unreacted ethylbenzene is recovered and recycled back to the reactor as a

physical mass flow. Recycle also occurs in the form of heat exchange (again in

the styrene process) and sometimes as information, e.g., a specification that two

variable temperatures must equal each other. The sequential-modular solution

strategy is based upon knowing all inputs to a module and using these to

calculate all outputs. When an input stream to a module is the output of a

downstream module (i.e., there is recycle), calculations cannot be performed for

the upstream module because one of its inputs is not yet known. This is

illustrated in Fig. 4.7; unit 1 cannot be calculated because input stream 4 is the

output of unit 2; nor can unit 2 be calculated because input stream 2 is an

output of unit 1. This same problem of circular reasoning was encountered in

Example 1. This dilemma in the sequential modular solution scheme can be

tL. B. Evans, Computer-Aided Design (CAD): Advances in Process Flowsheeting Systems, “Recent

Developments in Chemical Process and Plant Design,” Y. A. Liu, H. A. McGee, Jr., and W. R.

Epperly, eds., pp. 261-288, Wiley, New York, 1987.