Page 162 - Plant design and economics for chemical engineers

P. 162

136 PLANT DESIGN AND ECONOMICS FOR CHEMICAL ENGINEERS

3. The academic version of the process invention program (PIP) contains several

examples, as follows:

HDAl-hydrodealkylation of toluene to produce benzene

CYHEXl-cyclohexane production by hydrogenation of benzene

STYRl-styrene production from ethylbenzene

XYLl-production of m-xylene from toluene

ANHYDl-reaction of acetone and acetic acid to form acetic anhydride

BUTALl-alkylation reaction of butene-1 and isobutane to produce iso-octane

Select the “new plant design” mode and the “look at existing flow sheet” option, and

follow the synthesis steps for one of these processes. ‘Obtain the current flow sheet as

output at each level of the synthesis procedure. Also list the heuristics used at each

step.

4. Generate an alternative design for the process selected in Problem 3. Select the “new

plant design” mode and the option “generate alternative to an existing flow sheet.”

There are many inputs that may be changed to produce an alternative flow sheet. A

simple one is to input a new product rate, the process flow diagram will not change,

but the mass and energy balances and equipment sizes and costs will. For example,

double the product flow rate. More interesting changes may be introduced by

changing process constraints such as reaction temperature and pressure, or even

changing the choice of constraints. For example, replacing a specified constraint such

as reactant molar ratio with another, such as the composition of the purge stream.

5. For the methanol synthesis process illustrated in Fig. 4-1, Example 1, assume that

there are algorithms for calculating the outputs of each process unit from the inputs.

Determine how many stream variables must be specified and decide what these

should be so that a unique solution exists for the mass and energy balances. Identify

all recycle loops, tear streams for these loops, and a calculation sequence.

6. Repeat Example 4 for the styrene synthesis process with a different selection for the

tear streams to determine a new calculation sequence.

7. For a process flow sheet obtained in Problem 3, assume that algorithms are available

to calculate the outputs from each process unit from known inputs. Determine the

number of stream variables that must be specified, decide what they should be,

identify all recycle loops, select tear streams for these loops, and establish a calcula-

tion sequence.

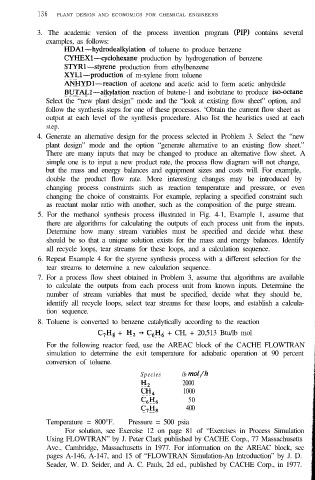

8. Toluene is converted to benzene catalytically according to the reaction

C,H, + Hz + C,H, + CH, + 20,513 Btu/lb mol

For the following reactor feed, use the AREAC block of the CACHE FLOWTRAN

simulation to determine the exit temperature for adiabatic operation at 90 percent

conversion of toluene.

Species lb mol/h

HZ 2000

(334 1000

Cd% 50

C7HS 400

Temperature = 800°F. Pressure = 500 psia

For solution, see Exercise 12 on page 81 of “Exercises in Process Simulation

Using FLOWTRAN” by J. Peter Clark published by CACHE Corp., 77 Massachusetts

Ave., Cambridge, Massachusetts in 1977. For information on the AREAC block, see

pages A-146, A-147, and 15 of “FLOWTRAN Simulation-An Introduction” by J. D.

Seader, W. D. Seider, and A. C. Pauls, 2d ed., published by CACHE Corp., in 1977.