Page 23 - Polymer-based Nanocomposites for Energy and Environmental Applications

P. 23

2 Polymer-based Nanocomposites for Energy and Environmental Applications

Particle Fiber Flake Laminar Filled

composite composite composite composite composite

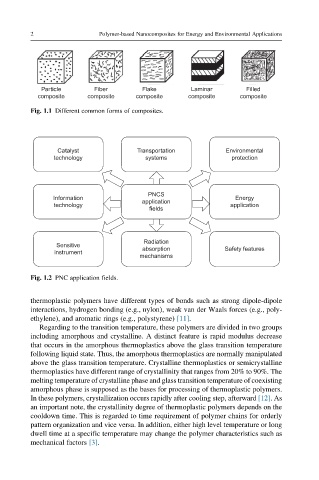

Fig. 1.1 Different common forms of composites.

Catalyst Transportation Environmental

technology systems protection

PNCS

Information application Energy

technology application

fields

Radiation

Sensitive

instrument absorption Safety features

mechanisms

Fig. 1.2 PNC application fields.

thermoplastic polymers have different types of bonds such as strong dipole-dipole

interactions, hydrogen bonding (e.g., nylon), weak van der Waals forces (e.g., poly-

ethylene), and aromatic rings (e.g., polystyrene) [11].

Regarding to the transition temperature, these polymers are divided in two groups

including amorphous and crystalline. A distinct feature is rapid modulus decrease

that occurs in the amorphous thermoplastics above the glass transition temperature

following liquid state. Thus, the amorphous thermoplastics are normally manipulated

above the glass transition temperature. Crystalline thermoplastics or semicrystalline

thermoplastics have different range of crystallinity that ranges from 20% to 90%. The

melting temperature of crystalline phase and glass transition temperature of coexisting

amorphous phase is supposed as the bases for processing of thermoplastic polymers.

In these polymers, crystallization occurs rapidly after cooling step, afterward [12].As

an important note, the crystallinity degree of thermoplastic polymers depends on the

cooldown time. This is regarded to time requirement of polymer chains for orderly

pattern organization and vice versa. In addition, either high level temperature or long

dwell time at a specific temperature may change the polymer characteristics such as

mechanical factors [3].