Page 691 - Polymer-based Nanocomposites for Energy and Environmental Applications

P. 691

636 Polymer-based Nanocomposites for Energy and Environmental Applications

252 m

20 MW

178 m

10 MW

150 m

7.5 MW

124 m

5.0 MW 126 m

112 m

15 m

0.01 MW

50 m

40 m 0.6 MW

0.5 MW

20 m

0.1 MW

19801985 1990 1995 2000 2005 2010 2015 2020

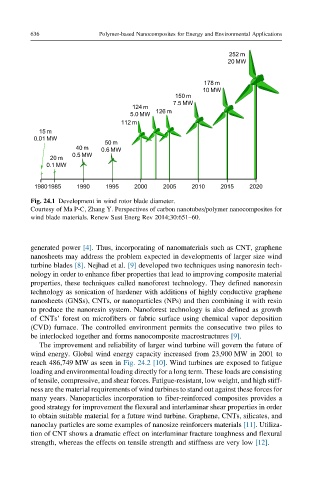

Fig. 24.1 Development in wind rotor blade diameter.

Courtesy of Ma P-C, Zhang Y. Perspectives of carbon nanotubes/polymer nanocomposites for

wind blade materials. Renew Sust Energ Rev 2014;30:651–60.

generated power [4]. Thus, incorporating of nanomaterials such as CNT, graphene

nanosheets may address the problem expected in developments of larger size wind

turbine blades [8]. Nejhad et al. [9] developed two techniques using nanoresin tech-

nology in order to enhance fiber properties that lead to improving composite material

properties, these techniques called nanoforest technology. They defined nanoresin

technology as sonication of hardener with additions of highly conductive graphene

nanosheets (GNSs), CNTs, or nanoparticles (NPs) and then combining it with resin

to produce the nanoresin system. Nanoforest technology is also defined as growth

of CNTs’ forest on microfibers or fabric surface using chemical vapor deposition

(CVD) furnace. The controlled environment permits the consecutive two piles to

be interlocked together and forms nanocomposite macrostructures [9].

The improvement and reliability of larger wind turbine will govern the future of

wind energy. Global wind energy capacity increased from 23,900 MW in 2001 to

reach 486,749 MW as seen in Fig. 24.2 [10]. Wind turbines are exposed to fatigue

loading and environmental loading directly for a long term. These loads are consisting

of tensile, compressive, and shear forces. Fatigue-resistant, low weight, and high stiff-

ness are the material requirements of wind turbines to stand out against these forces for

many years. Nanoparticles incorporation to fiber-reinforced composites provides a

good strategy for improvement the flexural and interlaminar shear properties in order

to obtain suitable material for a future wind turbine. Graphene, CNTs, silicates, and

nanoclay particles are some examples of nanosize reinforcers materials [11]. Utiliza-

tion of CNT shows a dramatic effect on interlaminar fracture toughness and flexural

strength, whereas the effects on tensile strength and stiffness are very low [12].