Page 20 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 20

Installation, Maintenance, and Repair of Horizontal Pumps 5

sleeves. Pump suction and discharge will normally have 150 lb raised

face flanges .

Mechanical seals provided in ANSI pumps are normally unbalanced,

single inside, but single outside seals are also quite common. Face mate-

rials are often carbon versus ceramic or tungsten carbide. Other materi-

als can be substituted where applicable. Seal flush is usually configured

as recirculation from pump discharge.

Motors: TEFC (totally enclosed fan cooled) 460 volt (560 in Canada),

three phase at 60 Hertz are standard drivers for North American applica-

tions.

Base Plates: Normally fabricated from steel plate with smaller base

plates cast. Pump and motor are mounted on the base plate and connected

with a coupling. For maintenance and repair work the coupling will have

to be removed and the pump internals can be removed from the pump case

without disturbing the piping.

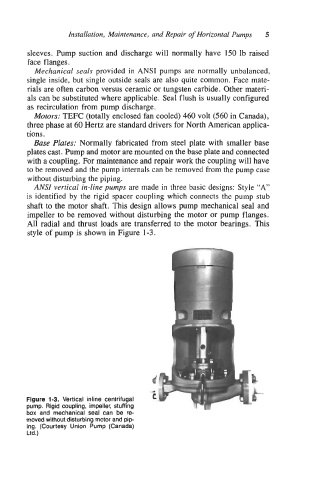

ANSI vertical in-line pumps are made in three basic designs: Style “A”

is identified by the rigid spacer coupling which connects the pump stub

shaft to the motor shaft. This design allows pump mechanical seal and

impeller to be removed without disturbing the motor or pump flanges.

All radial and thrust loads are transferred to the motor bearings. This

style of pump is shown in Figure 1-3.

Figure 1-3. Vertical inline centrifugal

pump. Rigid coupling, impeller, stuffing

box and mechanical seal can be re-

moved without disturbing motor and pip

ing. (Courtesy Union Pump (Canada)

Ltd.)