Page 276 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 276

258 Major Process Equipment Maintenance and Repair

!

- ----A

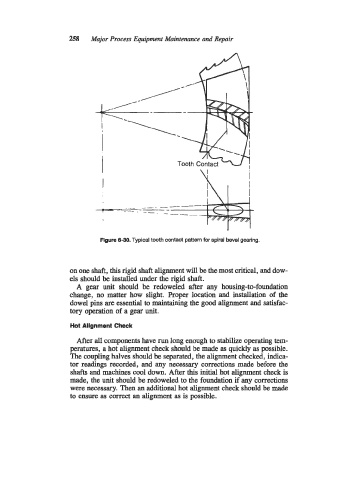

Figure 6-30. Typical tooth contact pattern for spiral bevel gearing.

on one shaft, this rigid shaft alignment will be the most critical, and dow-

els should be installed under the rigid shaft.

A gear unit should be redoweled after any housing-to-foundation

change, no matter how slight. Proper location and installation of the

dowel pins are essential to maintaining the good alignment and satisfac-

tory operation of a gear unit.

Hot Alignment Check

After all components have run long enough to stabilize operating tem-

peratures, a hot alignment check should be made as quickly as possible.

The coupling halves should be separated, the alignment checked, indica-

tor readings recorded, and any necessary corrections made before the

shafts and machines cool down. After this initial hot alignment check is

made, the unit should be redoweled to the foundation if any corrections

were necessary. Then an additional hot alignment check should be made

to ensure as correct an alignment as is possible.