Page 54 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 54

Installation, Maintenance, and Repair of Horizontal Pumps 39

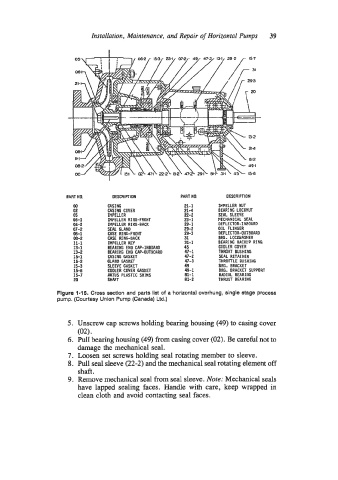

PART NO. DESCRIPTION PART NO. DESCRIPTION

00 WING 21-1 IMPELLER NUT

02 wrffi COVER 21-4 BEARING LOCKNUT

05 IHPELLER 22-2 SEAL SLEEVE

06-1 IFIPELLER RING-FRONT 23-1 MECHANICAL SEAL

06-2 IMPELLER RING-BACK 29-1 DEFLECTOR-I NZOARD

07-2 SEAL GLAND 29-2 OIL FLINGER

08-1 CASE RING-FRONT 29-3 DEFLECTOR- WTBDARO

08- 2 CASE RING-BACK 31 ERG. LOCKWASHER

11-1 IMPELLER KEY 31-1 BEARING BACKUP RING

13-1 BEARING END CAP-INBOARD 45 COOLER COVER

13-2 BEARING END CAP-OUTBOARD 47-1 THROAT BUSHING

15-1 CASING GASKET 47-2 SEAL RETAINER

15-2 GLAND GASKl3 47-3 THROllLE 6USHING

15-3 SLEEVE GASKET 49 BRG. BRACKET

15-6 COOLER COVER GASKET 49-1 ERG. BRACKET SUPPORT

15-7 ARTUS PLASTIC SHIMS 81-1 RADIAL BEARIlG

20 SHAFT 81-2 THRUST BEARING

Figure 1-15. Crass section and parts list of a horizontal overhung, single stage process

pump. (Courtesy Union Pump (Canada) Ltd.)

5. Unscrew cap screws holding bearing housing (49) to casing cover

(02).

6. bull bearing housing (49) from casing cover (02). Be careful not to

damage the mechanical seal.

7. Loosen set screws holding seal rotating member to sleeve.

8. Pull seal sleeve (22-2) and the mechanical seal rotating element off

shaft.

9. Remove mechanical seal from seal sleeve. Nore: Mechanical seals

have lapped sealing faces. Handle with care, keep wrapped in

clean cloth and avoid contacting seal faces.