Page 307 - Practical Ship Design

P. 307

Machinery Selection 265

the cost of gearing andor the need for separate pumps for one alternative whereas

another may use direct drive and have engine driven pumps included in the main

engine price.

9.1.6 Running costs

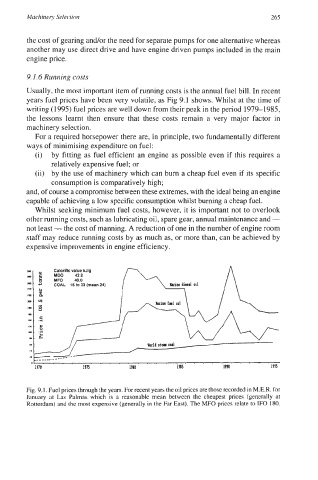

Usually, the most important item of running costs is the annual fuel bill. In recent

years fuel prices have been very volatile, as Fig 9.1 shows. Whilst at the time of

writing (1995) fuel prices are well down from their peak in the period 1979-1985,

the lessons learnt then ensure that these costs remain a very major factor in

machinery selection.

For a required horsepower there are, in principle, two fundamentally different

ways of minimising expenditure on fuel:

(i) by fitting as fuel efficient an engine as possible even if this requires a

relatively expensive fuel; or

(ii) by the use of machinery which can bum a cheap fuel even if its specific

consumption is comparatively high;

and, of course a compromise between these extremes, with the ideal being an engine

capable of achieving a low specific consumption whilst burning a cheap fuel.

Whilst seeking minimum fuel costs, however, it is important not to overlook

other running costs, such as lubricating oil, spare gear, annual maintenance and -

not least - the cost of manning. A reduction of one in the number of engine room

staff may reduce running costs by as much as, or more than, can be achieved by

expensive improvements in engine efficiency.

m , __ Calorific value kJh A

3 COAL 15to33(mean24) I \ Wine diad oil

..-

I , , . , , . , , , . , , , .

1910 1915 1980 198s 1990 1995

Fig. 9.1. Fuel prices through the years. For recent years the oil prices are those recorded in M.E.R. for

January at Las Palmas which is a reasonable mean between the cheapest prices (generally at

Rotterdam) and the most expensive (generally in the Far East). The MFO prices relate to IF0 180.