Page 315 - Practical Ship Design

P. 315

Machinen Selection 213

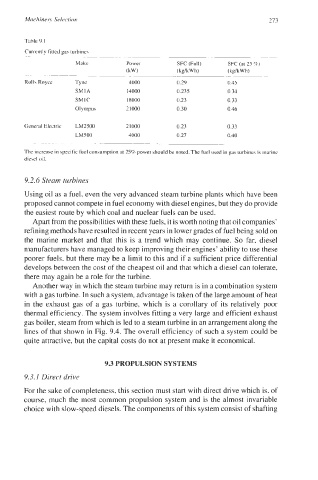

Tdble 9 I

Currently fitted gd\ turbines

~ ~~

~~

~

Make Power SFC (Full) SFC (at 25 &)

(kW) (kgkWh) (kgkwh)

-

~~~ ~ _.

Roll\ Royce Tyne 4000 0 29 0 45

SMlA 14000 0 235 0 34

SMlC I8000 0 23 0 33

Olympus 21000 0 30 0 46

General Electric LM2500 2 1 000 0.23 0.33

LM500 4000 0.27 0.40

The increase in specific fuel consumption at 25% power should be noted. The fuel used in gas turbines is marine

die\el oil.

9.2.6 Steam turbines

[Jsing oil as a fuel, even the very advanced steam turbine plants which have been

proposed cannot compete in fuel economy with diesel engines, but they do provide

the easiest route by which coal and nuclear fuels can be used.

Apart from the possibilities with these fuels, it is worth noting that oil companies’

refining methods have resulted in recent years in lower grades of fuel being sold on

the marine market and that this is a trend which may continue. So far, diesel

manufacturers have managed to keep improving their engines’ ability to use these

poorer fuels, but there may be a limit to this and if a sufficient price differential

develops between the cost of the cheapest oil and that which a diesel can tolerate,

there may again be a role for the turbine.

Another way in which the steam turbine may return is in a combination system

with a gas turbine. In such a system, advantage is taken of the large amount of heat

in the exhaust gas of a gas turbine, which is a corollary of its relatively poor

thermal efficiency. The system involves fitting a very large and efficient exhaust

gas boiler, steam from which is led to a steam turbine in an arrangement along the

lines of that shown in Fig. 9.4. The overall efficiency of such a system could be

quite attractive, but the capital costs do not at present make it economical.

9.3 PROPULSION SYSTEMS

9.3.1 Direct drive

For the sake of completeness, this section must start with direct drive which is, of

course, much the most common propulsion system and is the almost invariable

choice with slow-speed diesels. The components of this system consist of shafting