Page 341 - Practical Ship Design

P. 341

298 Chapter 10

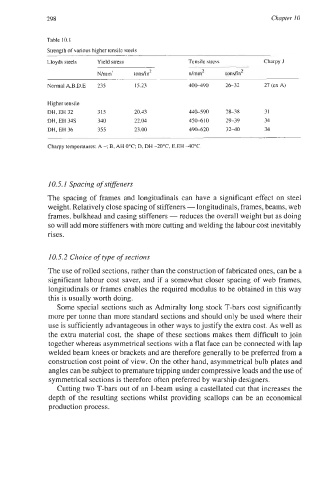

Table 10.1

Strength of various higher tensile steels

Lloyds steels Yield stress Tensile stress CharpY J

Nlmm' tons/in2 n/mrn2 tons/in2

Normal A,B,D,E 235 15.23 400-490 26-32 27 (ex A)

Higher tensile

DH, EH 32 315 20.43 440-590 28-38 31

DH, EH 34s 340 22.04 450410 29-39 34

DH, EH 36 355 23.00 490-620 3240 34

Charpy temperatures: A -; B, AH 0°C; D, DH -20"C, E,EH 40°C.

10.5. I Spacing of stifSeners

The spacing of frames and longitudinals can have a significant effect on steel

weight. Relatively close spacing of stiffeners - longitudinals, frames, beams, web

frames, bulkhead and casing stiffeners - reduces the overall weight but as doing

so will add more stiffeners with more cutting and welding the labour cost inevitably

rises.

10.5.2 Choice of type of sections

The use of rolled sections, rather than the construction of fabricated ones, can be a

significant labour cost saver, and if a somewhat closer spacing of web frames,

longitudinals or frames enables the required modulus to be obtained in this way

this is usually worth doing.

Some special sections such as Admiralty long stock T-bars cost significantly

more per tonne than more standard sections and should only be used where their

use is sufficiently advantageous in other ways to justify the extra cost. As well as

the extra material cost, the shape of these sections makes them difficult to join

together whereas asymmetrical sections with a flat face can be connected with lap

welded beam knees or brackets and are therefore generally to be preferred from a

construction cost point of view. On the other hand, asymmetrical bulb plates and

angles can be subject to premature tripping under compressive loads and the use of

symmetrical sections is therefore often preferred by warship designers.

Cutting two T-bars out of an I-beam using a castellated cut that increases the

depth of the resulting sections whilst providing scallops can be an economical

production process.