Page 113 - Practical Well Planning and Drilling Manual

P. 113

Section 1 revised 11/00/bc 1/17/01 2:56 PM Page 89

1.4.19

Casing Design [ ]

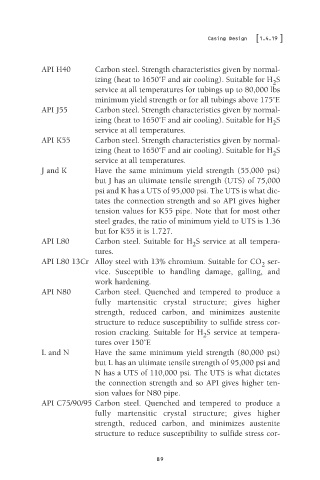

API H40 Carbon steel. Strength characteristics given by normal-

izing (heat to 1650˚F and air cooling). Suitable for H S

2

service at all temperatures for tubings up to 80,000 lbs

minimum yield strength or for all tubings above 175˚F.

API J55 Carbon steel. Strength characteristics given by normal-

izing (heat to 1650˚F and air cooling). Suitable for H S

2

service at all temperatures.

API K55 Carbon steel. Strength characteristics given by normal-

izing (heat to 1650˚F and air cooling). Suitable for H S

2

service at all temperatures.

J and K Have the same minimum yield strength (55,000 psi)

but J has an ultimate tensile strength (UTS) of 75,000

psi and K has a UTS of 95,000 psi. The UTS is what dic-

tates the connection strength and so API gives higher

tension values for K55 pipe. Note that for most other

steel grades, the ratio of minimum yield to UTS is 1.36

but for K55 it is 1.727.

API L80 Carbon steel. Suitable for H S service at all tempera-

2

tures.

API L80 13Cr Alloy steel with 13% chromium. Suitable for CO ser-

2

vice. Susceptible to handling damage, galling, and

work hardening.

API N80 Carbon steel. Quenched and tempered to produce a

fully martensitic crystal structure; gives higher

strength, reduced carbon, and minimizes austenite

structure to reduce susceptibility to sulfide stress cor-

rosion cracking. Suitable for H S service at tempera-

2

tures over 150˚F.

L and N Have the same minimum yield strength (80,000 psi)

but L has an ultimate tensile strength of 95,000 psi and

N has a UTS of 110,000 psi. The UTS is what dictates

the connection strength and so API gives higher ten-

sion values for N80 pipe.

API C75/90/95 Carbon steel. Quenched and tempered to produce a

fully martensitic crystal structure; gives higher

strength, reduced carbon, and minimizes austenite

structure to reduce susceptibility to sulfide stress cor-

89