Page 301 - Practical Well Planning and Drilling Manual

P. 301

Section 2 revised 11/00/bc 1/17/01 12:04 PM Page 277

Cementing Program [ ]

2.7.5

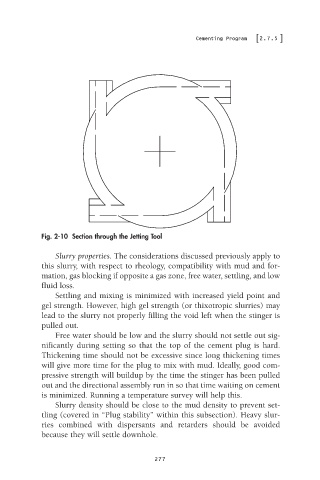

Fig. 2-10 Section through the Jetting Tool

Slurry properties. The considerations discussed previously apply to

this slurry, with respect to rheology, compatibility with mud and for-

mation, gas blocking if opposite a gas zone, free water, settling, and low

fluid loss.

Settling and mixing is minimized with increased yield point and

gel strength. However, high gel strength (or thixotropic slurries) may

lead to the slurry not properly filling the void left when the stinger is

pulled out.

Free water should be low and the slurry should not settle out sig-

nificantly during setting so that the top of the cement plug is hard.

Thickening time should not be excessive since long thickening times

will give more time for the plug to mix with mud. Ideally, good com-

pressive strength will buildup by the time the stinger has been pulled

out and the directional assembly run in so that time waiting on cement

is minimized. Running a temperature survey will help this.

Slurry density should be close to the mud density to prevent set-

tling (covered in “Plug stability” within this subsection). Heavy slur-

ries combined with dispersants and retarders should be avoided

because they will settle downhole.

277