Page 10 - Pressure Vessel Design Manual

P. 10

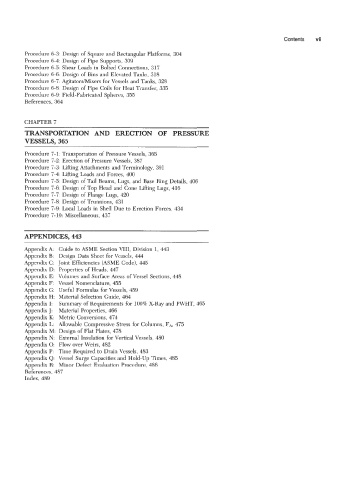

Contents vii

Procedure 6-3: Design of Square and Rectangular Platforms, 304

Procedure 6-4: Design of Pipe Supports, 309

Procedure 6-5: Shear Loads in Bolted Connections, 317

Procedure 6-6: Design of Bins and Elevated Tanks, 318

Procedure 6-7: AgitatordMixers for Vessels and Tanks, 328

Procedure 6-8: Design of Pipe Coils for Heat Transfer, 335

Procedure 6-9: Field-Fabricated Spheres, 355

References, 364

CHAPTER 7

TRANSPORTATION AND ERECTION OF PRESSURE

VESSELS, 365

Procedure 7-1: Transportation of Pressure Vessels, 365

Procedure 7-2: Erection of Pressure Vessels, 387

Procedure 7-3: Lifting Attachments and Terminology, 391

Procedure 7-4: Lifting Loads and Forces, 400

Procedure 7-5: Design of Tail Beams, Lugs, and Base Ring Details, 406

Procedure 7-6: Design of Top Head and Cone Lifting Lugs, 416

Procedure 7-7: Design of Flange Lugs, 420

Procedure 7-8: Design of Trunnions, 431

Procedure 7-9: Local Loads in Shell Due to Erection Forces, 434

Procedure 7-10: Miscellaneous, 437

APPENDICES, 443

Appendix A: Guide to ASME Section VIII, Division 1, 443

Appendix B: Design Data Sheet for Vessels, 444

Appendix C: Joint Efficiencies (ASME Code), 445

Appendix D: Properties of Heads, 447

Appendix E: Volumes and Surface Areas of Vessel Sections, 448

Appendix F: Vessel Nomenclature, 455

Appendix G: Useful Formulas for Vessels, 459

Appendix H: Material Selection Guide, 464

Appendix I: Summary of Requirements for 100% X-Ray and PWHT, 465

Appendix J: Material Properties, 466

Appendix K: Metric Conversions, 474

Appendix L: Allowable Compressive Stress for Columns, FA, 475

Appendix M: Design of Flat Plates, 478

Appendix N: External Insulation for Vertical Vessels, 480

Appendix 0: Flow over Weirs, 482

Appendix P: Time Required to Drain Vessels, 483

Appendix Q: Vessel Surge Capacities and Hold-Up Times, 485

Appendix R: Minor Defect Evaluation Procedure, 486

References, 487

Index, 489