Page 153 - Primer on Enhanced Oil Recovery

P. 153

Chemical EOR 143

significant part of infected water channels into the production wells. The reservoirs

inhomogeneity also makes water breakthrough to develop much faster as, due to

the predominant movement of water in a highly permeable interlayer, layered-

inhomogeneous formations greatly reduce the sweep efficiency of the reservoir by

the direct waterflooding.

The solution of these problems is based on adding polymers to the injected

water, i.e. the use of so named polymer flooding. The mechanism of polymer flood-

ing is determined by three main factors:

1. Increase of injected liquid viscosity (as compared to just water). This reduces the capillary

number. When a water-soluble polymer is added to water at a concentration of

0.01 0.1%, the viscosity of the resulting polymer solution increases 3 4 times. This

leads to the apparent viscosity of the polymer, during the propagation through the pores,

to increases up to 20 times. In this regard, polymer solutions are particularly effective in

heterogeneous reservoirs and in fields with high viscosity of oil.

2. Water-soluble polymers used in polymer flooding are by themselves anionic surfactants.

Propagation of surfactants in the reservoir will reduce the surface tension. On top of this,

in the process of polymer flooding, more surfactant additives are used in the polymer

solution. The resulting complex of polymer molecules and surfactants has a molecular

weight higher than the molecular weight of the polymer, and hence a higher viscosity.

The reduction in interfacial surface tension makes it possible to ensure that residual oil is

washed off from the surface of the pore channels behind the displacement front too.

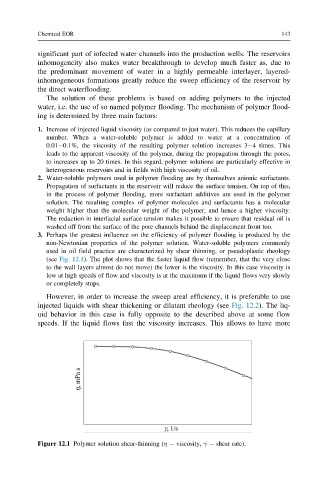

3. Perhaps the greatest influence on the efficiency of polymer flooding is produced by the

non-Newtonian properties of the polymer solution. Water-soluble polymers commonly

used in oil field practice are characterized by shear thinning, or pseudoplastic rheology

(see Fig. 12.1). The plot shows that the faster liquid flow (remember, that the very close

to the wall layers almost do not move) the lower is the viscosity. In this case viscosity is

low at high speeds of flow and viscosity is at the maximum if the liquid flows very slowly

or completely stops.

However, in order to increase the sweep areal efficiency, it is preferable to use

injected liquids with shear thickening or dilatant rheology (see Fig. 12.2). The liq-

uid behavior in this case is fully opposite to the described above at some flow

speeds. If the liquid flows fast the viscosity increases. This allows to have more

Figure 12.1 Polymer solution shear-thinning (η viscosity, γ shear rate).