Page 161 - Principles of Catalyst Development

P. 161

CATALYST CHARACTERIZATION 149

TO NITROGEN ELECTRONIC

TO HELIUM MANOMETER

TO VACUUM PUMPS

VACUUM

VALVE

CALIBRATED

VOLUME

VACUUM

COUPLING

FLASK

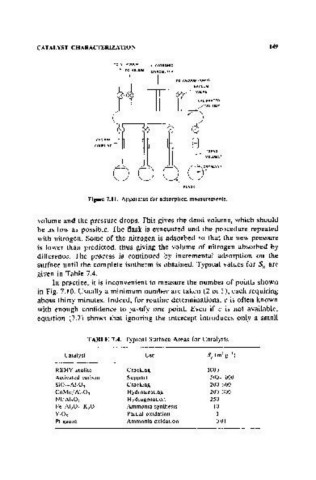

Figure 7.11. Apparatus for adsorption measurements.

volume and the pressure drops. This gives the dead volume, which should

be as low as possible. The flask is evacuated and the procedure repeated

with nitrogen. Some of the nitrogen is adsorbed so that the new pressure

is lower than predicted, thus giving the volume of nitrogen absorbed by

difference. The process is continued by incremental adsorption on the

surface until the complete isotherm is obtained. Typical values for Sg are

given in Table 7.4.

In practice, it is inconvenient to measure the number of points shown

in Fig. 7.10. Usually a minimum number are taken (2 or 3), each requiring

about thirty minutes. Indeed, for routine determinations, c is often known

with enough confidence to justify one point. Even if c is not available,

equation (7.7) shows that ignoring the intercept introduces only a small

TABLE 7.4. Typical Surface Areas for Catalysts

Catalyst Use Sg(m'g~l)

REHY zeolite Cracking 1000

Activated carbon Support 500- :1000

SiOrAl,OJ Cracking 200-S00

CoMo/Al,O, Hydrotreating 200-300

Nij Al,O, Hydrogenation 250

Fe-A1,Or K,O Ammonia synthesis 10

V,Os Partial oxidation 1

Pt gauze Ammonia oxidation 0.01