Page 9 - Process Equipment and Plant Design Principles and Practices by Subhabrata Ray Gargi Das

P. 9

CHAPTER

1

General aspects of process design

1.1 Process

An industrial process converts feed material to useful product(s) of desired quality in commercial

scale. The steps involved in such a process need to be technically viable, safe, and economical. Such

steps involve heat, mass, momentum transfer, and chemical reaction, independently or in combination.

A process is always designed to perform a specific function. Such a task can be heating of a material

from an initial to a final temperature, mixing of several streams to achieve homogeneity, separation of a

multicomponent material stream or chemical conversion of a reactor feed to products and their sub-

sequent separation.

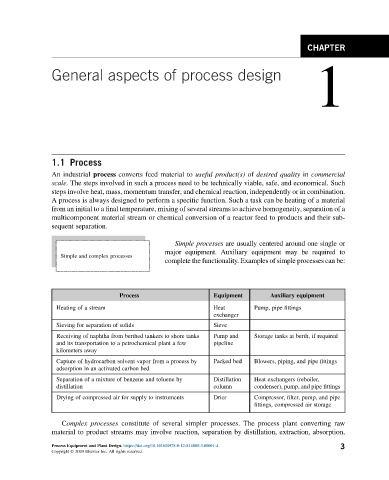

Simple processes are usually centered around one single or

major equipment. Auxiliary equipment may be required to

Simple and complex processes

complete the functionality. Examples of simple processes can be:

Process Equipment Auxiliary equipment

Heating of a stream Heat Pump, pipe fittings

exchanger

Sieving for separation of solids Sieve

Receiving of naphtha from berthed tankers to shore tanks Pump and Storage tanks at berth, if required

and its transportation to a petrochemical plant a few pipeline

kilometers away

Capture of hydrocarbon solvent vapor from a process by Packed bed Blowers, piping, and pipe fittings

adsorption in an activated carbon bed

Separation of a mixture of benzene and toluene by Distillation Heat exchangers (reboiler,

distillation column condenser), pump, and pipe fittings

Drying of compressed air for supply to instruments Drier Compressor, filter, pump, and pipe

fittings, compressed air storage

Complex processes constitute of several simpler processes. The process plant converting raw

material to product streams may involve reaction, separation by distillation, extraction, absorption,

Process Equipment and Plant Design. https://doi.org/10.1016/B978-0-12-814885-3.00001-4 3

Copyright © 2020 Elsevier Inc. All rights reserved.