Page 272 - Reciprocating Compressors Operation Maintenance

P. 272

Overhaul and Repair of Reciprocating Compressors 257

or scoring. Also, the amount of cylinder oiling should be determined, that

is, determine whether the cylinder is being over-oiled or not enough oil is

being fed to the cylinder. Adjustment to lubricator feed can be done at

this time.

A more detailed inspection should be performed at every overhaul At

that time, the piston and piston rods are removed, exact measurements of

the bore are made, and the general condition of the bore is determined,

TYPES OF INSPECTION

There are two types of inspections.

1. Visual. This inspection determines whether any roughness, scuffing,

or scratching has taken place.

2. Measurements. Measurements are taken to determine what wear has

taken place and whether that wear is within limits allowing opera-

tion to continue. If measurements show that the wear is beyond

acceptable limits, the measurements determine what repair proce-

dures should be implemented.

CYLINDER BORE MEASUREMENTS

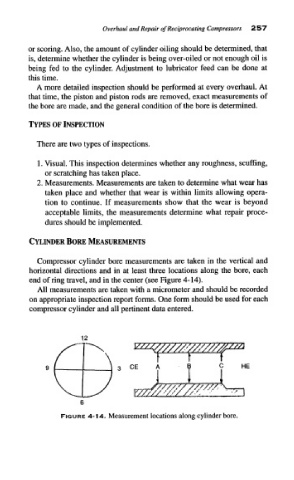

Compressor cylinder bore measurements are taken in the vertical and

horizontal directions and in at least three locations along the bore, each

end of ring travel, and in the center (see Figure 4-14).

All measurements are taken with a micrometer and should be recorded

on appropriate inspection report forms. One form should be used for each

compressor cylinder and all pertinent data entered.

6

FIGURE 4-14. Measurement locations along cylinder bore.