Page 484 - Refining Biomass Residues for Sustainable Energy and Bioproducts

P. 484

Processing food waste for the production of platform chemicals 441

DHMF

Monosaccharides Mineral acids, polar

solvent, heteropolyacids, LA

ionic liquids

Dehydration HMF HMTHFA

Disaccharides

Hydrolysis Liquid alkanes

Polysaccharides FDCA

BrØnsted acids HFCA

(sulfuric, hydrochloric,

Amberlyst)

Termoset resins Polyurethanes Polyesters Polyamides

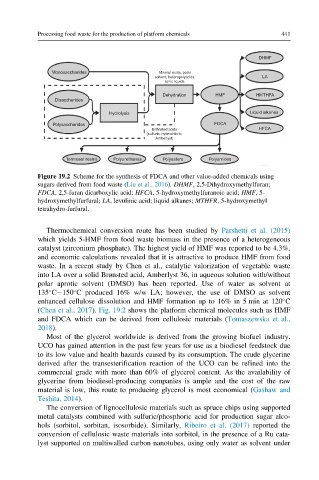

Figure 19.2 Scheme for the synthesis of FDCA and other value-added chemicals using

sugars derived from food waste (Liu et al., 2016). DHMF, 2,5-Dihydroxymethylfuran;

FDCA, 2,5-furan dicarboxylic acid; HFCA, 5-hydroxymethylfuranoic acid; HMF,5-

hydroxymethylfurfural; LA, levulinic acid; liquid alkanes; MTHFR, 5-hydroxymethyl

tetrahydro-furfural.

Thermochemical conversion route has been studied by Parshetti et al. (2015)

which yields 5-HMF from food waste biomass in the presence of a heterogeneous

catalyst (zirconium phosphate). The highest yield of HMF was reported to be 4.3%,

and economic calculations revealed that it is attractive to produce HMF from food

waste. In a recent study by Chen et al., catalytic valorization of vegetable waste

into LA over a solid Brønsted acid, Amberlyst 36, in aqueous solution with/without

polar aprotic solvent (DMSO) has been reported. Use of water as solvent at

135 C 150 C produced 16% w/w LA; however, the use of DMSO as solvent

enhanced cellulose dissolution and HMF formation up to 16% in 5 min at 120 C

(Chen et al., 2017). Fig. 19.2 shows the platform chemical molecules such as HMF

and FDCA which can be derived from cellulosic materials (Tomaszewska et al.,

2018).

Most of the glycerol worldwide is derived from the growing biofuel industry.

UCO has gained attention in the past few years for use as a biodiesel feedstock due

to its low value and health hazards caused by its consumption. The crude glycerine

derived after the transesterification reaction of the UCO can be refined into the

commercial grade with more than 60% of glycerol content. As the availability of

glycerine from biodiesel-producing companies is ample and the cost of the raw

material is low, this route to producing glycerol is most economical (Gashaw and

Teshita, 2014).

The conversion of lignocellulosic materials such as spruce chips using supported

metal catalysts combined with sulfuric/phosphoric acid for production sugar alco-

hols (sorbitol, sorbitan, isosorbide). Similarly, Ribeiro et al. (2017) reported the

conversion of cellulosic waste materials into sorbitol, in the presence of a Ru cata-

lyst supported on multiwalled carbon nanotubes, using only water as solvent under