Page 289 - Robot Builder's Bonanza

P. 289

258 USING SERVO MOTORS

digital servo means the motor is drawing more current from its power source, which means

batteries tend not to last as long between charges.

For most robotics applications, digital servos are not required. You can get by with the less

expensive standard analog servos. An exception is when building a walking robot, where the

extra torque of digital servos comes in handy. Six- legged walking bots may use 12 and even

18 servos just for the legs. The higher torque helps to offset the added weight of all those

servos.

Electronics for Controlling a Servo

Unlike a DC motor, which runs if you simply attach a battery to it, a servo motor requires

proper interface electronics in order to rotate its output shaft. While the need for interface

electronics may complicate to some degree your use of servos, the electronics are actually

rather simple. And if you plan on operating your servos with a PC or microcontroller (such as

the Arduino, PICAXE, or BASIC Stamp), all you need for the job is a few lines of software.

A DC motor typically needs power transistors, MOSFETs, or relays if it is interfaced to a

computer. A servo, on the other hand, can be directly coupled to a circuit or microcontroller

with no additional electronics. All of the power- handling needs are taken care of by the

control circuitry in the servo, saving you the hassle. This is one of the key benefits of using

servos with computer- controlled robots.

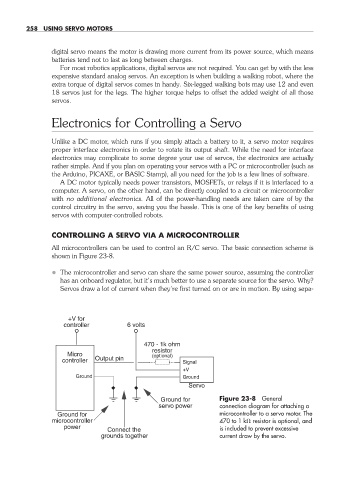

CONTROLLING A SERVO VIA A MICROCONTROLLER

All microcontrollers can be used to control an R/C servo. The basic connection scheme is

shown in Figure 23- 8.

• The microcontroller and servo can share the same power source, assuming the controller

has an onboard regulator, but it’s much better to use a separate source for the servo. Why?

Servos draw a lot of current when they’re first turned on or are in motion. By using sepa-

+V for

controller 6 volts

470 - 1k ohm

resistor

Micro (optional)

controller Output pin Signal

+V

Ground Ground

Servo

Ground for Figure 23- 8 General

servo power connection diagram for attaching a

Ground for microcontroller to a servo motor. The

microcontroller 470 to 1 k resistor is optional, and

power is included to prevent excessive

Connect the

grounds together current draw by the servo.

23-chapter-23.indd 258 4/21/11 11:51 AM