Page 313 - Robot Builder's Bonanza

P. 313

282 MOUNTING MOTORS AND WHEELS

Pillow block Wheel

and brackets

Locking Figure 24- 15 Flexible rubber tubing or

nut Nut

Screw hose may be used to connect a motor shaft to

a wheel with its own axle. Shown here is an

Motor Hose axle made with a machine screw, but any type

coupler Pillow block

of axle compatible with the inner diameter of

the tubing will work. Use hose clamps around

the tubing if the fit is too large.

G Try to get tubing the same size or slightly smaller than the shaft diameter. Prior to fitting, you

can put the tubing into hot water to soften and expand it. With the tubing still warm, slip it over

the shaft. Wait for the tubing to cool, then do the twist test to see if it’ll work as a shaft coupling.

Tubing is sized in different ways— it is sometimes sold by its inside diameter (I.D.) and

sometimes by the outside diameter (O.D.). Bring your parts into the store for a dry fit. Tubing

sold by the foot is the most economical, as you can buy just short lengths at a time. You don’t

need much.

Working with Different Shaft Types

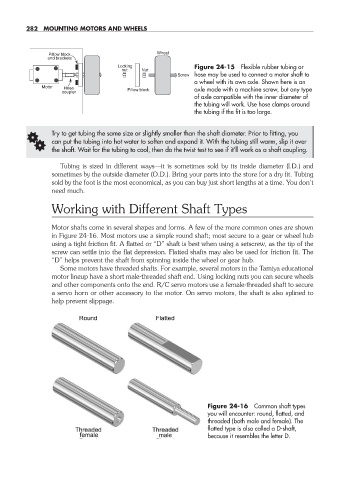

Motor shafts come in several shapes and forms. A few of the more common ones are shown

in Figure 24- 16. Most motors use a simple round shaft; most secure to a gear or wheel hub

using a tight friction fit. A flatted or “D” shaft is best when using a setscrew, as the tip of the

screw can settle into the flat depression. Flatted shafts may also be used for friction fit. The

“D” helps prevent the shaft from spinning inside the wheel or gear hub.

Some motors have threaded shafts. For example, several motors in the Tamiya educational

motor lineup have a short male- threaded shaft end. Using locking nuts you can secure wheels

and other components onto the end. R/C servo motors use a female-threaded shaft to secure

a servo horn or other accessory to the motor. On servo motors, the shaft is also splined to

help prevent slippage.

Figure 24- 16 Common shaft types

you will encounter: round, flatted, and

threaded (both male and female). The

flatted type is also called a D- shaft,

because it resembles the letter D.

24-chapter-24.indd 282 4/21/11 11:51 AM