Page 218 - Rock Mechanics For Underground Mining

P. 218

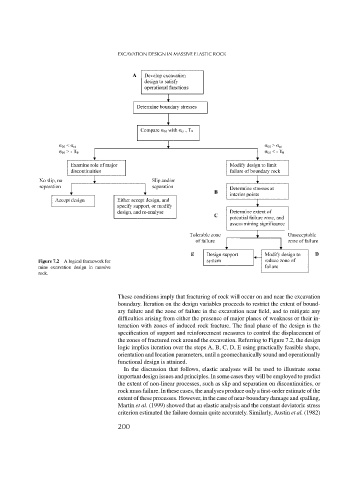

EXCAVATION DESIGN IN MASSIVE ELASTIC ROCK

Figure 7.2 A logical framework for

mine excavation design in massive

rock.

These conditions imply that fracturing of rock will occur on and near the excavation

boundary. Iteration on the design variables proceeds to restrict the extent of bound-

ary failure and the zone of failure in the excavation near field, and to mitigate any

difficulties arising from either the presence of major planes of weakness or their in-

teraction with zones of induced rock fracture. The final phase of the design is the

specification of support and reinforcement measures to control the displacement of

the zones of fractured rock around the excavation. Referring to Figure 7.2, the design

logic implies iteration over the steps A, B, C, D, E using practically feasible shape,

orientation and location parameters, until a geomechanically sound and operationally

functional design is attained.

In the discussion that follows, elastic analyses will be used to illustrate some

important design issues and principles. In some cases they will be employed to predict

the extent of non-linear processes, such as slip and separation on discontinuities, or

rock mass failure. In these cases, the analyses produce only a first-order estimate of the

extent of these processes. However, in the case of near-boundary damage and spalling,

Martin et al. (1999) showed that an elastic analysis and the constant deviatoric stress

criterion estimated the failure domain quite accurately. Similarly, Austin et al. (1982)

200