Page 167 - Root Cause Failure Analysis

P. 167

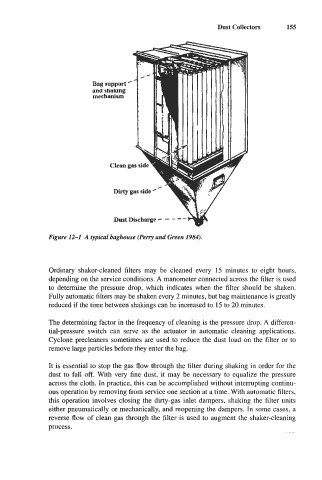

Dust Collectors 155

Figure 12-1 A

Ordinary shaker-cleaned filters may be cleaned every 15 minutes to eight hours,

depending on the service conditions. A manometer connected across the filter is used

to determine the pressure drop, which indicates when the filter should be shaken.

Fully automatic filters may be shaken every 2 minutes, but bag maintenance is greatly

reduced if the time between shakings can be increased to 15 to 20 minutes.

The determining factor in the frequency of cleaning is the pressure drop. A differen-

tial-pressure switch can serve as the actuator in automatic cleaning applications.

Cyclone precleaners sometimes are used to reduce the dust load on the filter or to

remove large particles before they enter the bag.

It is essential to stop the gas flow through the filter during shaking in order for the

dust to fall off. With very fine dust, it may be necessary to equalize the pressure

across the cloth. In practice, this can be accomplished without interrupting continu-

ous operation by removing from service one section at a time. With automatic filters,

this operation involves closing the dirty-gas inlet dampers, shaking the filter units

either pneumatically or mechanically, and reopening the dampers. In some cases, a

reverse flow of clean gas through the filter is used to augment the shaker-cleaning

process.