Page 47 - Rotating Machinery Pratical Solutions to Unbalance and Misalignment

P. 47

Resonance and Beat Frequencies

Equation (3.1) yields f =22.36 Hz. This is only a 10.6% change in

frequency for a 40% increase in mass.

In most cases, adding mass to a component is not practicable

and the component must be stiffened.

Example 3.2

In the system described in Example 3.1, the stiffness of the

object is increased by welding a bracket in place. The bracket

weighs 1 pound and increases the stiffness to 28,750 lb./ft. What

is the resulting new natural frequency?

The new mass is 21/32.2 or .6522 pounds. Using the new

mass and the new constant k, and substituting into Equation (3.1)

yields f = 33.42 Hz..

This change in the stiffness resulted in a 33.68% change in the

natural frequency of the object. This frequency change would be

adequate to keep the object from being excited by an external force

at 25 Hz.

Of course, the best way to solve the situation is to remove the

source of the original vibration. Generally, the vibrating source is

operating at a fixed speed and a significant reduction in its driving

force cannot be accomplished. Vibration isolators or additional

dampening can sometimes be added.

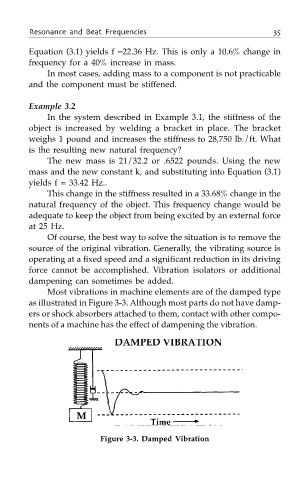

Most vibrations in machine elements are of the damped type

as illustrated in Figure 3-3. Although most parts do not have damp-

ers or shock absorbers attached to them, contact with other compo-

nents of a machine has the effect of dampening the vibration.

Figure 3-3. Damped Vibration