Page 172 - Schaum's Outline of Theory and Problems of Applied Physics

P. 172

CHAPTER 13

Elasticity

STRESS AND STRAIN

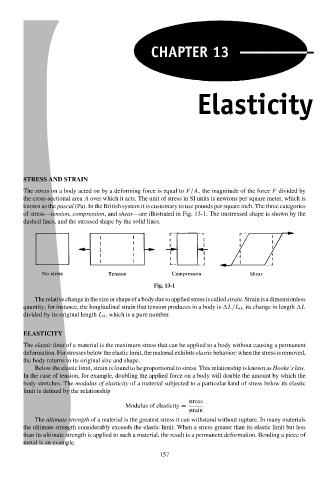

The stress on a body acted on by a deforming force is equal to F/A, the magnitude of the force F divided by

the cross-sectional area A over which it acts. The unit of stress in SI units is newtons per square meter, which is

known as the pascal (Pa). In the British system it is customary to use pounds per square inch. The three categories

of stress—tension, compression, and shear—are illustrated in Fig. 13-1. The unstressed shape is shown by the

dashed lines, and the stressed shape by the solid lines.

Fig. 13-1

Therelativechangeinthesizeorshapeofabodyduetoappliedstressiscalledstrain.Strainisadimensionless

quantity; for instance, the longitudinal strain that tension produces in a body is L/L 0 , its change in length L

divided by its original length L 0 , which is a pure number.

ELASTICITY

The elastic limit of a material is the maximum stress that can be applied to a body without causing a permanent

deformation. For stresses below the elastic limit, the material exhibits elastic behavior: when the stress is removed,

the body returns to its original size and shape.

Below the elastic limit, strain is found to be proportional to stress. This relationship is known as Hooke’s law.

In the case of tension, for example, doubling the applied force on a body will double the amount by which the

body stretches. The modulus of elasticity of a material subjected to a particular kind of stress below its elastic

limit is defined by the relationship

stress

Modulus of elasticity =

strain

The ultimatestrength of a material is the greatest stress it can withstand without rupture. In many materials

the ultimate strength considerably exceeds the elastic limit. When a stress greater than its elastic limit but less

than its ultimate strength is applied to such a material, the result is a permanent deformation. Bending a piece of

metal is an example.

157