Page 353 - Shale Shakers Drilling Fluid Systems

P. 353

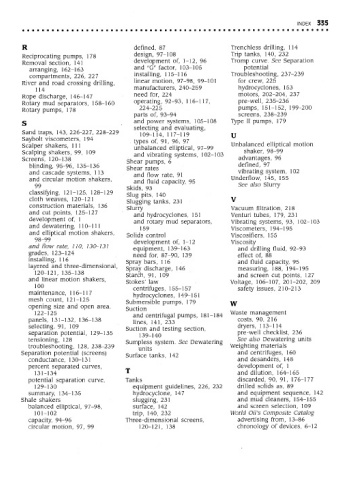

INDEX 335

R defined, 87 Trenchless drilling, 114

desi n

Reciprocating pumps, 178 § ' 97-108 Trip tanks, 140, 232

Removal section 141 development of, 1-12, 96 Tromp curve. See Separation

G

arranging 162-163 and " " f actor < 103-105 potential

compartments, 226, 227 installing, 115-116 Troubleshooting, 237-239

linear

River and road crossing drilling, motion, 97-98, 99-101 for crew, 225

114' manufacturers, 240-259 hydrocyclones, 153

Rope discharge 146-147 need for 224 motors, 202-204, 237

'

Rotary mud separators, 158-160 operating, 92-93, 116-117, pre-well, 235-236

Rotary pumps, 178 224-225 pumps, 151-152, 199-200

parts of, 93-94 screens, 238-239

g and power systems, 105-108 Type II pumps, 179

selecting and evaluating,

Sand traps, 143, 226-227, 228-229 109-114 117-119 U

Saybolt viscometers, 194 t e of 91 96 97

°

Scalper shakers, 111 unbalanced elliptical, 97-99 ^±1°^ ^^ mOtl n

Scalping shakers, 99, 109 and vibrati s£ stem' S; 102_ 103 shaker, 98-99

Screens, 120-138 shear numns f y advantages, 96

U

PS 6

blinding, 95-96, 135-136 |hear P ™ ' defined, 97

and cascade systems, 113 and flow rate 91 vibrating system, 102

and circular motion shakers, anrl f\ u[ d r . naritv on Underflow, 145, 155

Skids 93 " " See .,so Slurry

99

classifying, 121-125, 128-129 slue pits 140

cloth weaves, 120-121 Slugging'tanks, 231 V

construction materials, 136 slurry Vacuum filtration, 218

and cut points 125-127 and hydrocyclones, 151 Venturi tubes, 179, 231

development of, 1 ancl rotary mud separators, Vibrating systems, 93, 102-103

and dewatering, 110-111 159 Viscometers, 194-195

and elliptical motion shakers, Solids control Viscosifiers, 155

9

~ development of, 1-12 Viscosity

and flow rate, 110, 130-131 equipment, 139-163 and drilling fluid, 92-93

grades, 123-124 need for< 87_9 0/ 139 effect of, 88

installing, 116 Spray bars, 116 and fluid capacity, 95

measuring, 188, 194-195

layered and three-dimensional, Spray discharge/ 146

120 121, 135 138 Starch, 91, 109 and screen cut points, 127

and linear motion shakers, stokes, law Voltage, 106-107, 201-202, 209

100

^ centrifuges, 155-157 safety issues, 210-213

maintenance, 116-117 hydrocyclones, 149-151

mesh count, 121-125 Submersible pumps, 179 w

opening size and open area, Suction

122 125

T and centrifugal pumps, 181-184 Waste management

panels, 131-132, 136-138 lines 141 233 costs 90 216

'

'

selecting, 91, 109 Suction and'testing section, dryers 113-114

separation potential, 129-135 139-140 pre-well checklist, 236

tensioning, 128 Sumpless system. See Dewatering _ Se ^ /so Dewatering units

troubleshooting, 128, 238-239 ^nits Weighting materials

ancl centr u es

Separation potential (screens) surface tanks 142 if § < 160

conductance, 130-131 ' and desanders, 148

percent separated curves, development of, 1

131-134 T and dilution, 164-165

potential separation curve, Tanks discarded, 90, 91, 176-177

129-130 equipment guidelines, 226, 232 drilled solids as, 89

summary, 134-135 hydrocyclone, 147 and equipment sequence, 142

Shale shakers slugging, 231 and mud cleaners, 154-155

balanced elliptical, 97-98, surface, 142 and screen selection, 109

101-102 trip, 140, 232 World O;7's Composite Catalog

capacity, 94-96 Three-dimensional screens, advertising from, 13-86

circular motion, 97, 99 120-121, 138 chronology of devices, 6-12