Page 88 - Shale Shakers Drilling Fluid Systems

P. 88

HISTORICAL PERSPECTIVE 71

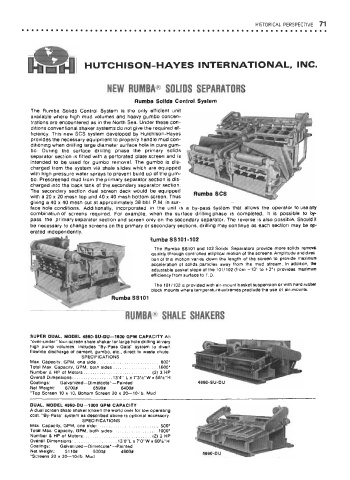

HUTCHISON-HAYES INTERNATIONAL, INC.

Rumba Solids Control System

The Rumba Solids Control System is the only efficient unit

available where high muci volumes and heavy gumbo concen-

trations are encountered as in the North Sea, Under these con-

ditions conventional shaker systems do not give the required ef-

ficiency. This new SCS system developed by Hutchison-Hayes

provides the necessary equipment to properly handle mud con-

ditioning when drilling large diameter surface hole in pure gum-

bo. During the surface drilling phase the primary solids

separator section is fitted with a perforated plate screen and is

intended to be used for gumbo removal. The gumbo is dis-

charged from the system via shale slides which are equipped

with high pressure water sprays to prevent build up of the gum-

bo, Presereened mud from the primary separator section is dis-

charged into the back tank of the secondary separator section.

The secondary section dual screen deck would be equipped

with a 20 x 20 mesh top and 40 x 40 mesh bottom screen. Thus

giving a 40 x 40 mesh cut at approximately 38 bbl, P.M. in sur-

face hole conditions, Additionally, incorporated in the unit is a by-pass system that allows the operator to use any

combination of screens required. For example, when the surface drilling phase is completed, it is possible to by-

pass the primary separator section and screen only on the secondary separator. The reverse is also possible. Should it

be necessary to change screens on the primary or secondary sections, drilling may continue as each section may be op-

erated independently.

Rumba SS101-102

The Rumba SS101 and 102 Solids Separators provide more solids removal

quickly through controlled elliptical motion of the screens. Amplitude and diree

{ion of this motion varies down the length of the screen to provide maximum

acceleration of solids particles away from the mud stream. In addition, the

adjustable oaskel slope of the 101/102 (from -13° to +3°) provides maximum

efficiency from surface to T.D.

The 101/102 is provided with air-mount basket suspension or with hard rubber

block mounts where temperature extremes preclude the use of air-rnounts,

RUMBA® SHALE SHAKERS

SUPER DUAL, MODEL 486Q-SU*DU—1609 6PM CAPACITY An

"over-under" four-screen shale shaker for large hole drilling at very

high pump volumes. Includes "By-Pass Gate" system to divert

flowline discharge of cement, gumbo, etc., direct to waste chute.

SPECIFICATIONS

Max. Capacity, GPM, one side .,, , 800*

Total Max. Capacity, GPM, both sides .. .1600*

Number & HP of Motors , ,,, (2) 3 HP

Overall Dimensions: . ,. ,13'4" I x 7'3Vfe"W x 58Vt"H

Coatings: Galvanized—Dimetcote*—Painted

Net Weight: 67QG# 6590# 640Q#

*Top Screen 10 x 10, Bottom Screen 20 x 20—10-lb. Mud

DUAL, MODEL 4860-DU—1000 GPM CAPACITY

A dual screen shale shaker known the world over for low operating

cost. "By-Pass" system as described above is optional accessory.

SPECIFICATIONS

Max. Capacity, GPM, one side: . , .. 500*

Total Max, Capacity, GPM, both sides: , 1000*

Number a HP of Motors: , ,.... (2) 3 HP

Overall Dimensions: 13'0"L x 7'0"W x 60WH

Coatings; Galvanized—Dimetcote*— Painted

Net Weight: 5110# 5000* 4800#

•Screens 20 x 20— 10-lb, Mud