Page 96 - Shale Shakers Drilling Fluid Systems

P. 96

HISTORICAL PERSPECTIVE 79

Superclone

Solids Centrifuge

Control

Separator

Centrifuge

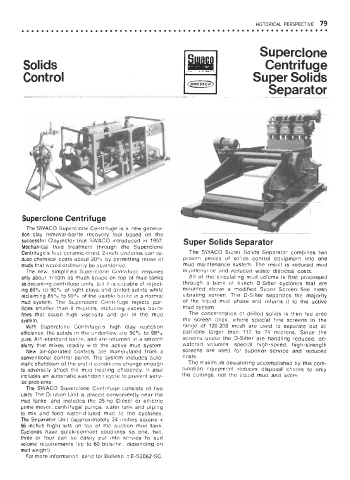

The SWACO Supcrcione Centrifuge is a new genera-

tion clay removal ~barite recovery fool based on the

successful Clayjector that SWACO introduced in 1957.

Mechanical fluid treatment through the Superclone

Centrifuge's four ceramic-lined, 2-inch cyclones can re- The SWACO Super Solids Separator combines two

duce chemical costs about 20% by permitting reuse of proven pieces of solids control equipment into one

muds that would ordinarily be abandoned. mud maintenance system. The result is reduced mud

The new, simplified Superdono Centrifuge requires maintenance and reduced waste disposal costs,

only about 1/10th as much space on top of mud tanks All of the circulating mud volume is first processed

as decanting centrifuge units, but it is capable of reject- through a bank of 4-inch D-Silter cyclones that are

ing 60% to 90°o of light ciays aid drilled solids while mounted above a modified Super Screen fine mesh

reclaiming 85% to 90% of the usable barite m a normal vibrating screen. The D-Silter separates the majority

mud system. The Superclone Centrifuge rejects par- of the liquid mud phase and returns it to the active

ticles smaller than 8 microns, including excess barite mud system.

fines that cause high viscosity and gel in the mud The concentration of drilled solids is then fed onto

system. the screen deck, where special fine screens in the

With Superclone Centrifuge's high clay rejection range of 120-200 rnesh are used to separate out a!f

efficiency, the solids in the underflow are 90% to 98% particles larger than 117 to 74 microns. Since the

pure, API-standard barite, and are returned in a smooth screens under the D-Silter are handling reduced, de-

slurry that mixes readily with the active mud system. watered volumes, special high-speed, high-strength

New air-operated controls are manipulated from a screens are used for superior service and reduced

conventional control panel. The system includes auto- costs.

matic shutdown of the unit if conditions change enough The maximum dewatering accomplished by this com-

to adversely affect the mud-treating efficiency. It also bination equipment reduces disposal chores to only

includes an automatic washdown cycle to prevent serv- the cuttings, not the liquid mud and water.

ice problems.

The SWACO Superclone Centrifuge consists of two

units. The Dilution Unit is placed conveniently near the

mud tanks, and includes the 25-hp Diese! or electric

prime mover, centrifugal pumps, water tank and piping

to mix and feed water-diluted mud to the cyclones.

The Separator Unit (approximately 24 inches square x

86 inches high) sits on top of the suction mud tank.

Cyclones have quick-connect couplings so one, two,

three or four can be easily put into service to suit

volume requirements (up to 60 bbls/hr.. depending on

mud weight).

For more information, send for Bulletin ^E-S3Q62-SC.