Page 39 - Shigley's Mechanical Engineering Design

P. 39

bud29281_ch01_002-030.qxd 11/11/2009 5:35 pm Page 14 pinnacle s-171:Desktop Folder:Temp Work:Don't Delete (Jobs):MHDQ196/Budynas:

14 Mechanical Engineering Design

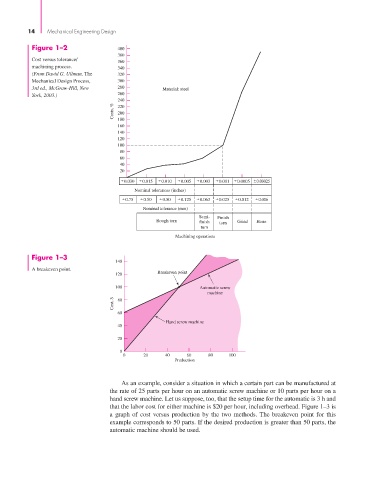

Figure 1–2 400

380

Cost versus tolerance/

360

machining process. 340

(From David G. Ullman, The 320

Mechanical Design Process, 300

3rd ed., McGraw-Hill, New 280 Material: steel

260

York, 2003.)

240

Costs, % 220

200

180

160

140

120

100

80

60

40

20

0.030 0.015 0.010 0.005 0.003 0.001 0.0005 0.00025

Nominal tolerances (inches)

0.75 0.50 0.50 0.125 0.063 0.025 0.012 0.006

Nominal tolerance (mm)

Semi- Finish

Rough turn finish turn Grind Hone

turn

Machining operations

Figure 1–3

140

A breakeven point.

120 Breakeven point

100 Automatic screw

machine

Cost, $ 80

60

Hand screw machine

40

20

0

0 20 40 60 80 100

Production

As an example, consider a situation in which a certain part can be manufactured at

the rate of 25 parts per hour on an automatic screw machine or 10 parts per hour on a

hand screw machine. Let us suppose, too, that the setup time for the automatic is 3 h and

that the labor cost for either machine is $20 per hour, including overhead. Figure 1–3 is

a graph of cost versus production by the two methods. The breakeven point for this

example corresponds to 50 parts. If the desired production is greater than 50 parts, the

automatic machine should be used.