Page 36 -

P. 36

1.3 Case studies 19

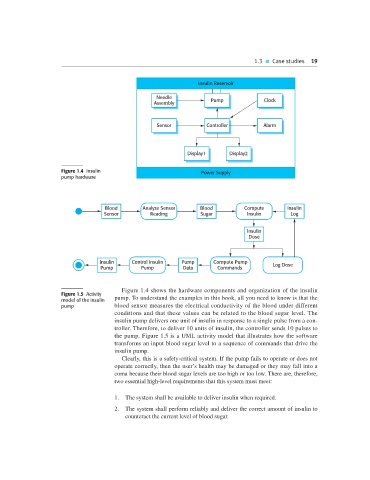

Insulin Reservoir

Needle

Assembly Pump Clock

Sensor Controller Alarm

Display1 Display2

Figure 1.4 Insulin Power Supply

pump hardware

Blood Analyze Sensor Blood Compute Insulin

Sensor Reading Sugar Insulin Log

Insulin

Dose

Insulin Control Insulin Pump Compute Pump Log Dose

Pump Pump Data Commands

Figure 1.4 shows the hardware components and organization of the insulin

Figure 1.5 Activity

model of the insulin pump. To understand the examples in this book, all you need to know is that the

pump blood sensor measures the electrical conductivity of the blood under different

conditions and that these values can be related to the blood sugar level. The

insulin pump delivers one unit of insulin in response to a single pulse from a con-

troller. Therefore, to deliver 10 units of insulin, the controller sends 10 pulses to

the pump. Figure 1.5 is a UML activity model that illustrates how the software

transforms an input blood sugar level to a sequence of commands that drive the

insulin pump.

Clearly, this is a safety-critical system. If the pump fails to operate or does not

operate correctly, then the user’s health may be damaged or they may fall into a

coma because their blood sugar levels are too high or too low. There are, therefore,

two essential high-level requirements that this system must meet:

1. The system shall be available to deliver insulin when required.

2. The system shall perform reliably and deliver the correct amount of insulin to

counteract the current level of blood sugar.