Page 253 - Steam Turbines--Design, Applications, and Rerating by Heinz-Bloch, Murari-Singh

P. 253

232 Chapter Twelve

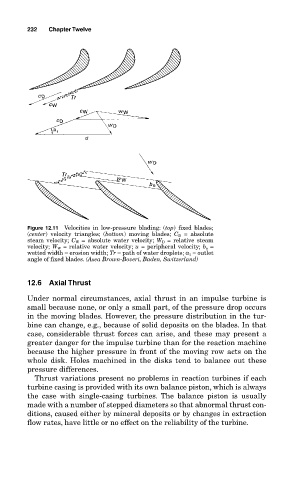

Figure 12.11 Velocities in low-pressure blading: (top) fixed blades;

(center) velocity triangles; (bottom) moving blades; C D = absolute

steam velocity; C W = absolute water velocity; W D = relative steam

velocity; W W = relative water velocity; u = peripheral velocity; b e =

wetted width = erosion width; Tr = path of water droplets; α 1 = outlet

angle of fixed blades. (Asea Brown-Boveri, Baden, Switzerland)

12.6 Axial Thrust

Under normal circumstances, axial thrust in an impulse turbine is

small because none, or only a small part, of the pressure drop occurs

in the moving blades. However, the pressure distribution in the tur-

bine can change, e.g., because of solid deposits on the blades. In that

case, considerable thrust forces can arise, and these may present a

greater danger for the impulse turbine than for the reaction machine

because the higher pressure in front of the moving row acts on the

whole disk. Holes machined in the disks tend to balance out these

pressure differences.

Thrust variations present no problems in reaction turbines if each

turbine casing is provided with its own balance piston, which is always

the case with single-casing turbines. The balance piston is usually

made with a number of stepped diameters so that abnormal thrust con-

ditions, caused either by mineral deposits or by changes in extraction

flow rates, have little or no effect on the reliability of the turbine.